When it comes to the non-destructive testing (NDT) of welds, this includes both surface detection and volumetric inspection. Continued advances in NDT technology enables improved detection of defects and sizing. Each technique has its own advantages and limitations, but in most cases, they can be complementary and combined to provide operators with the most comprehensive data.

Details

With over 30 different types of welding and the various stress combination loads can impose, there are several reasons why weld defects may occur. Because welding is responsible for joining materials together, the structural integrity of welds is imperative for capital assets and infrastructure everywhere including for oil and gas, chemical, nuclear, aerospace, marine and other industrial sectors.

Types of welds include, but are not limited to, the following.

- Girth welds: Typical in pipelines, girth weld inspection verifies the integrity of circumferential welds at pipeline joints.

- Butt welds: Two pieces of metal of the same plane are joined by butt welds which are subject to slag inclusion, porosity or cracking, for example.

- Corrosion Resistant Alloy (CRA) welds: Common in the offshore oil and gas sector, CRA welds require special attention and skills when performing ultrasonic testing (UT).

Dissimilar Metal Welds (DMW): DMW welds, susceptible to cracks and corrosion, are the result of different metals joining and can also be a challenge for UT, without the right equipment and procedure.

Electric Resistance Welding (ERW): ERW welding processes include spot welds and long seam welds for amalgamation of faying surfaces.

Spot welds are mostly used for joining multiple metal sheets together by applying pressure and heat to the weld area, usually in the automotive and sheet metal fabrication sectors.

Long seams are exactly what they sound like and usually require a volumetric NDT inspection method.

Friction Stir Welds (FSW): FSW are the result of solid-state joining process that employs a non-consumable tool to combine two facing workpieces, best qualified with eddy current testing, ultrasonic testing, or a combination of both methods.

These are the most common weld defects.

Weld Cracks

Weld cracks are the most critical welding defect.

- Hot cracks: Also known as hot shortness, hot fissuring, solidification cracking and liquation cracking, hot cracks typically occur during the welding process or the crystallization process of the weld joint.

- Cold cracks: Referred to as a spontaneous crack, cold cracks typically occur after solidification is complete in the welding process, occurring in both butt welds and fillet welds.

- Crater cracks: Usually forming near the end of the weld, crater cracks appear when there isn’t enough volume to overcome shrinkage of the weld metal.

- Toe cracks: Also a cold crack, toe cracks can be the result of moisture content present in the welded area.

- Root cracks: Starting at the root, these longitudinal cracks partly extend into the weld due to high shrinkage stresses.

- Heat Affected Zone (HAZ) cracks: HAZ cracks are located in the area between the weld and the base, parent material. They can either be parallel to the weld or oriented to the weld bead.

Lack of Fusion

Lack of Fusion (LoF) or incomplete fusion happens when there is no proper fusion between the weld metal and base metal, or between adjoining weld beads. The gap in the joint weakens the weld.

Lack of Penetration

Lack of Penetration (LoP) is when the weld metal doesn’t completely fill the joint thickness. This occurs sometimes when there is too much space between the metal being welded together.

Slag Inclusion

Slag is a glassy by-product of certain types of welding. Slag inclusion is a weld defect that occurs when the shielding material used when welding melts in the weld or on the weld zone surface.

Porosity

Porosity develops with the presence of bubble-filled welds, the result of metal contamination and trapped gases. This typically produces a weaker weld prone to collapse.

When it comes to the non-destructive testing (NDT) of welds, this includes both surface detection and volumetric inspection. Continued advances in NDT technology enables improved detection of defects and sizing. Each technique has its own advantages and limitations, but in most cases, they can be complementary and combined to provide operators with the most comprehensive data.

Weld Surface Inspection

Eddy Current Array (ECA), Tangential Eddy Current Array (TECA™), and Alternating Current Field Measurement (ACFM®) are preferred methods for weld surface defect inspection. The material, the requirements and the working environment where inspection is required helps dictate when to use each method.

For carbon steel weld inspection, a reliable tool is Eddyfi Technologies' Tangential Eddy Current Array (TECA) Sharck™ probes. TECA uses ECA technology to introduce currents tangential to the surface of the weld under test to detect and size surface-breaking cracks. Sharck butt and fillet weld probes allow fast inspection of cracks without extensive surface preparation, making it easier to detect and size weld cracks in carbon steel. The best portable electromagnetic NDT system for rapid crack assessment, the Eddyfi Reddy® enables weld inspection, simultaneously scanning the weld cap, toe area, and heat-affected zone for longitudinal and transverse cracks without paint or coating removal. For stainless steel welds and other non-ferrous joints, ECA is an ideal technique. Padded ECA probes, for example, adapt to geometry variations in almost every direction, making the probes perfect for examining weld beads, transitions, and HAZ.

For subsea or offshore weld inspection, ACFM —an electromagnetic inspection technique that introduces an alternating current into the surface of a weld to detect surface-breaking cracks— offers a proven and practical solution. The TSC Amigo2 was specifically designed for the detection of surface-breaking cracks in subsea and offshore environments. Immediate defect sizing and recording is a major benefit, and optimal performance when inspecting underwater structural welds. The Amigo2 is engineered around a highly advanced signal acquisition and processing system able to process data quickly with smoother, high resolution indications that increase the detectability of small defects. The ACFM subsea inspection system finds flaws in structural node welds on jackets, welded plate structures, performing weld inspection with standard and single-pass array probes, through thick coatings and in the splash zone.

Weld Volumetric Inspection

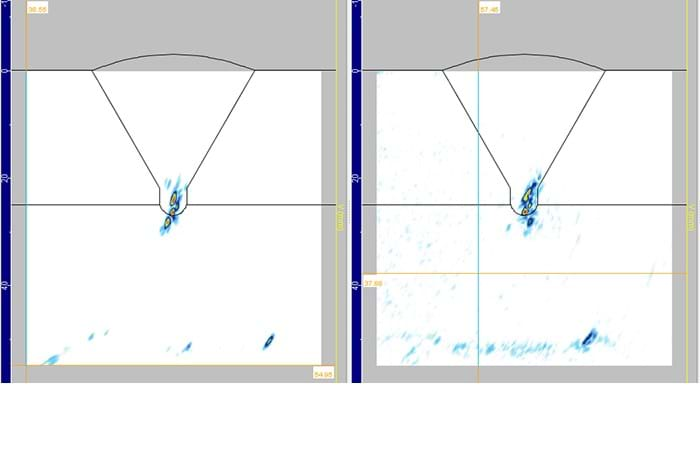

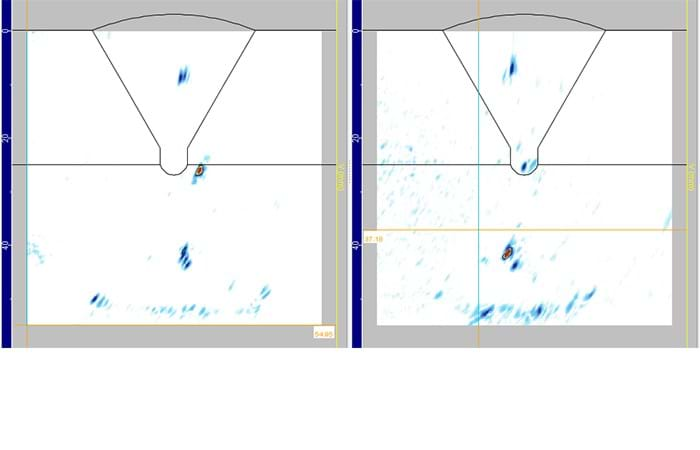

Phased Array Ultrasonic Testing (PAUT) in combination with Total Focusing Method (TFM) is optimal for volumetric inspection of welds, sometimes in combination with Time-of-flight Diffraction (TOFD).

The M2M Gekko® and M2M Mantis™ are portable PAUT flaw detectors that incorporate TFM and TOFD. Through the user-friendly interface, Capture™, inspectors can quickly configure the Gekko and Mantis units, scan, and analyze the collected data with confidence. Capture simplifies scanning using TFM and PAUT, streamlining analysis of TFM data to overcome the limitations with each technique. Multi-group weld inspection procedures are fully covered. Thick welds and CRA or stainless steel welds benefit from a 128-element aperture. A complex geometry dedicated solution for fillet welds in Y and T joints provides real-time display of the weld inspection. The onboard library of weld preps allows better oil and gas weld inspection, power generation thick weld inspection, dissimilar material weld inspection, automotive and railway laser weld inspection and spot weld inspection.

Both surface and volumetric inspection methods are complementary for a complete weld defect assessment. Eddyfi Technologies offers weld inspection solutions for detecting the variety of flaws across many different types of welds.