Eddy Current Testing (ECT)

Eddy current testing is an electromagnetic testing technique usually used to inspect non-ferromagnetic materials.

Details

How it Works

In its most basic form — the single-element eddy current testing probe — a copper wire is excited with an alternating electrical current. This wire produces a magnetic field around itself in the direction ascertained by the right-hand rule. This magnetic field oscillates at the same frequency as the current running through the coil. When the coil approaches a conductive material, currents opposed to the ones in the coil are induced in the material — eddy currents.

A defect in the conductive material disturbs the path of eddy currents, creating a local magnetic field that changes the balance of the system. This can be detected by measuring the changes in impedance in the coil, which is a telltale sign of the presence of defects.

With time, different technologies were developed such as Pulsed Eddy Current (PEC) that detects flaws and corrosion in ferrous materials and Eddy Current Array (ECA) that uses multiples coils together to get an effective reading of a large area on a single pass.

Ask an ExpertBenefits

Several benefits are derived from eddy current testing:

- It is suited to volumetric flaws such as corrosion, wear, and large porosities, as well as cracking.

- It can detect surface-breaking, near-surface, and far-surface defects.

- ECT probes don’t need to be in contact with the part under inspection.

- Eddy current testing can be used in applications other than flaw detection.

- Parts under test require only minimal preparation.

Tubing Applications

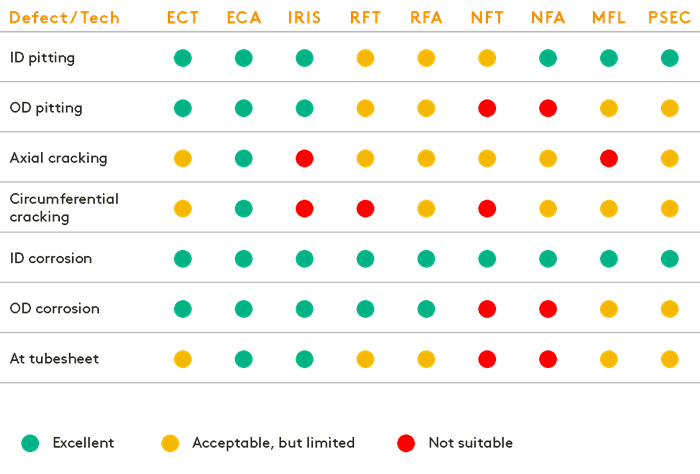

Detection Capabilities According to Defect Type in Tubing

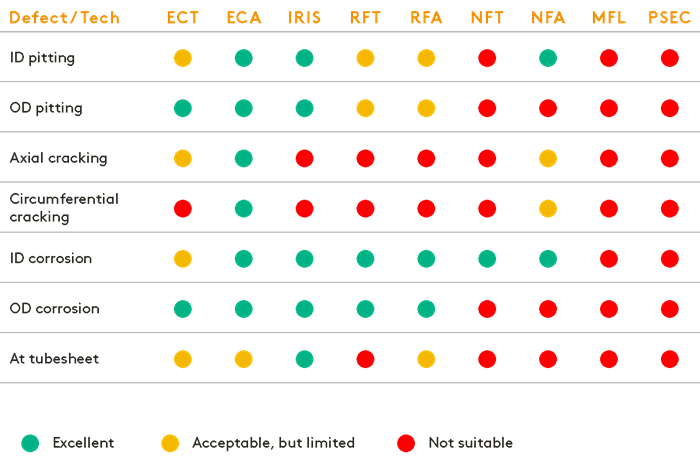

Sizing Capabilities According to Defect Type in Tubing

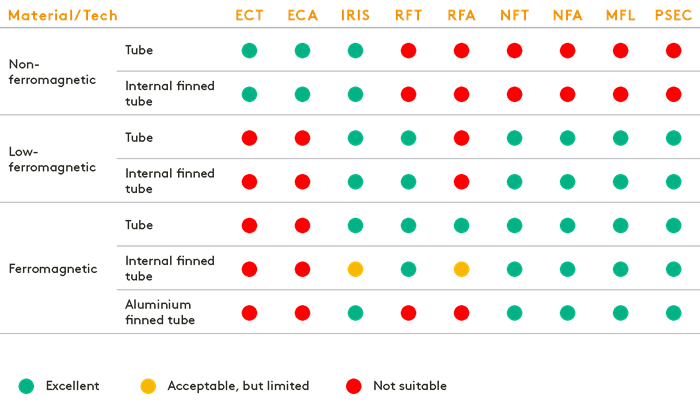

Suitability According to Tubing Material

Surface Applications

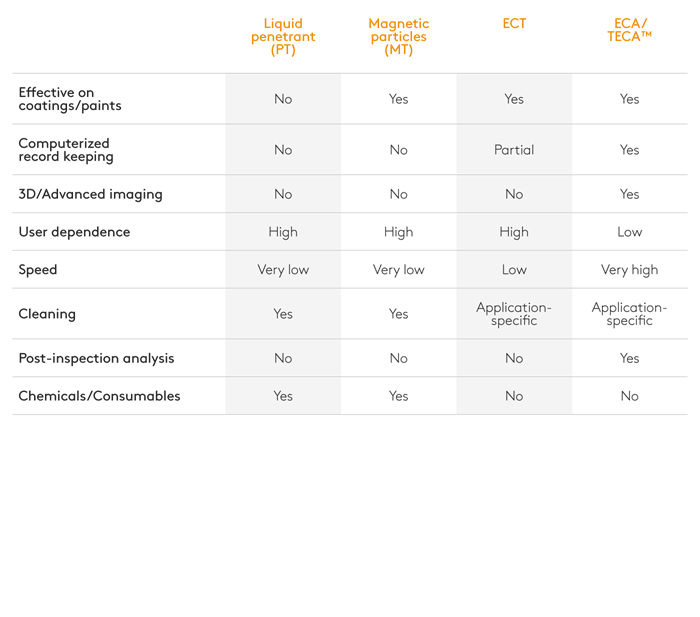

When it comes to surface applications, the performance of any given inspection technique depends greatly on the specific conditions — mostly the types of materials and defects, but also surface conditions, cleanliness, etc. However, in most situations, the following are true:

Learn more