The use of longitudinal wave mode in guided wave testing has often been dismissed, but we think it deserves a longer look.

In the guided wave industry, torsional wave mode is most commonly used because of its ease to transmit the wave mode and interpret results. T(0,1) is the only torsional wave mode that exists within the frequency range of testing for Long Range Ultrasonics. It is also nondispersive throughout this frequency range which means that its velocity is constant at all frequencies. Use of torsional wave mode requires only two rings of transducers for testing as operators need to control only the direction of the wave propagation.

When it comes to longitudinal testing, there are two wave modes present: L(0,1) which is dispersive, and L(0,2) which is nondispersive at the frequency of testing. In order to test using the L(0,2) mode alone, inspectors require the second ring to control the wave propagation direction and a third ring to suppress the unwanted L(0,1) wave mode. This suppression immediately increases the complexity of software and electronics. Furthermore, it is well known that in liquid filled lines the longitudinal wave can transmit through liquid content at girth welds, causing reverberations that make inspection more challenging for this type of application.

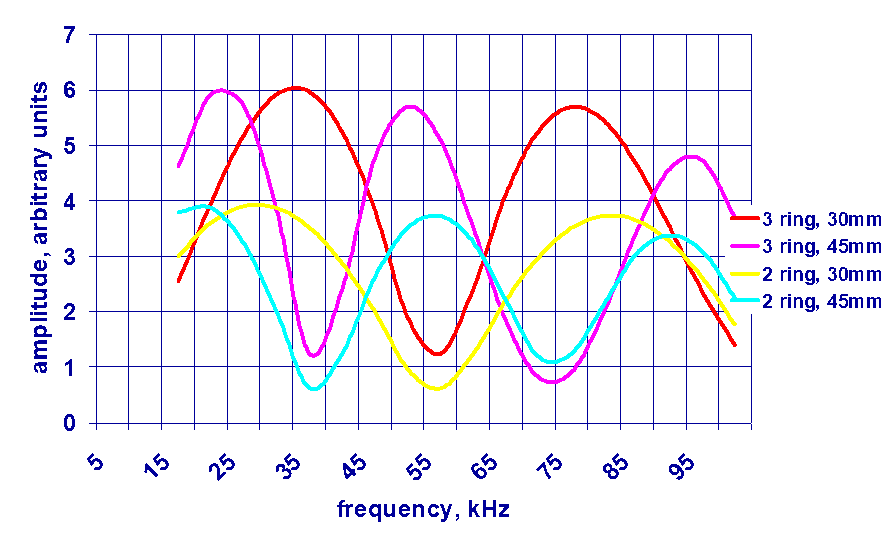

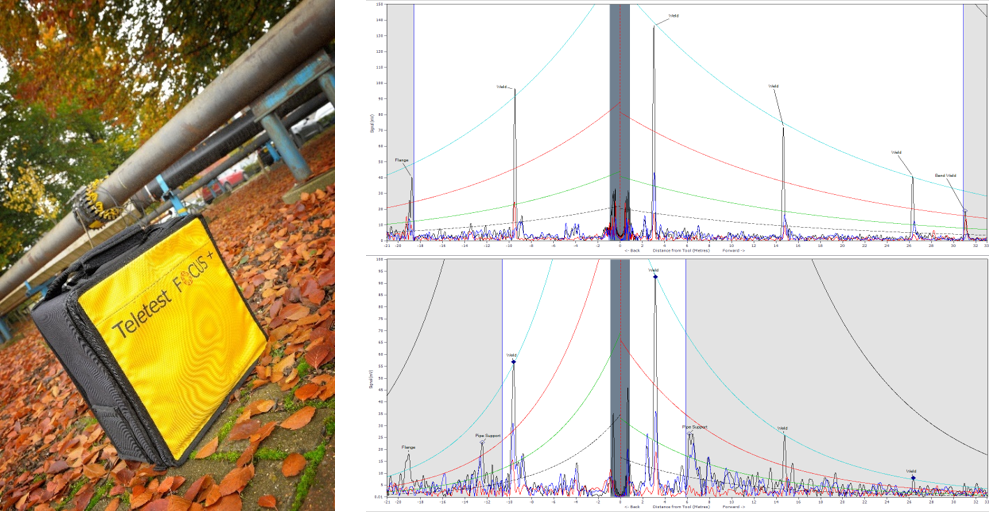

While other equipment manufacturers don’t use the longitudinal wave mode due to its apparent complexity, we recognize the greater benefit and have made longitudinal testing accessible. With our multimode system capable of producing both longitudinal and torsional wave modes from the same tool, the Teletest Focus+ is the most capable system on the market. The sophisticated nature of the Focus+ electronics, 24 transmit and 24 receive circuits with internal switching for expansion to 40 channels, allowed us to increase our product range to a 5-ring torsional solution. This facilitates 3-ring torsional testing at two different ring spacings (30mm and 45mm). The direct benefit is being able to test over the broadest frequency range of any guided wave product, giving the correct balance between maximum penetration and resolution.

The graph below shows the increased input of three rings compared to two with increased frequency range for testing with two different spacings on the same tool.

So, what would Eddyfi Technologies recommend when purchasing the Teletest Focus+? Torsional testing has become the default, and therefore our 5-ring torsional modules provide the best method for testing thanks to its unrivaled penetration and most expansive frequency range. However, we would highly advise operators not neglect the use of longitudinal wave mode for applications where it could make the difference between a partial and complete inspection. Take a road crossing, for example. It is well documented that longitudinal wave has lower attenuation in coated or buried lines1 potentially increasing the diagnostic length, or in other applications previously deemed unsuitable for guided waves due to geometry like axially welded pipe supports.

The image below is an example of the effect of axially welded pipe supports with longitudinal and torsional data. In this case, the longitudinal diagnostic length was 50m compared to 15m for torsional.

Instead of dismissing longitudinal wave mode as not worth investigating due to being too complicated, the Focus+ deals with these issues directly, making it the most advanced guided wave system commercially available. For more information on the benefits and latest advancements of guided wave technology for your long range inspections, check out the Sonyks™ solution or contact our experts today!

1 Eli Leinov, Michael J.S. Lowe, Peter Cawley, “Ultrasonic isolation of buried pipes”, Journal of Sound and Vibration 363 (2016) 225–239.