Offshore inspections pose an impressive challenge in themselves. Large offshore platforms are exposed to unforgiving elements 24/7, the entire operation and environment depends on the structural integrity of the large pillars or caissons and their ability to withstand the forces found in this volatile environment. Seawater, marine growth, and large waves are just a few of the elements that can breakdown the risers support system.

Long-range ultrasonic testing (LRUT) or GWT techniques are ideal for offshore riser inspections and offer significant advantages to alternative methods. Both internal and external corrosion can be monitored, only requiring an access point between the flange and sea level. Employing a pulse-echo system designed for testing large volumes of material from a single test point, it is the superior candidate for pipelines that are buried, encased in a sleeve, elevated aboveground, or in this case, out at sea that would otherwise require the need for a diving operation.

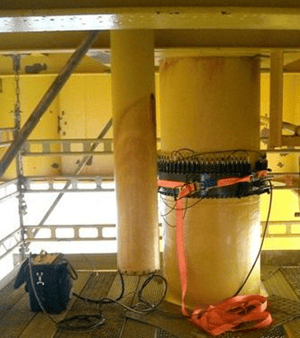

Previously, the GWT solution was deployed in a field trial to inspect caissons on an offshore installation. Direct access is typically difficult, but the inspection solution was able to inspect the entire length of the caisson from the topside. The purpose for this assessment was to determine the caisson’s condition prior to removal. Using both torsional and longitudinal wave modes, the instrument used multimode modules to get complete data results (check out this blog on why two modes are better than one). In this case, torsional was the ideal testing condition given the wall thickness of the caisson.

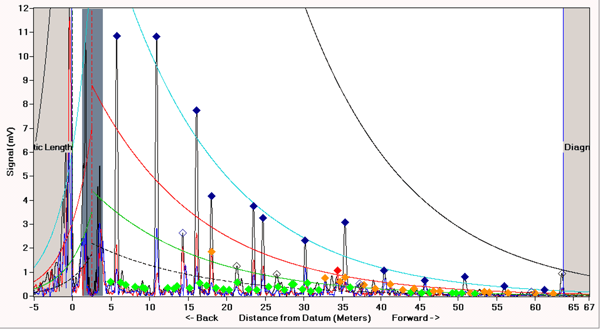

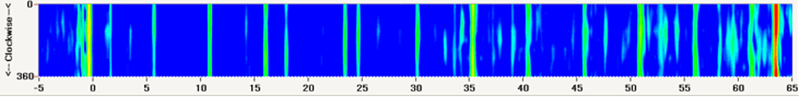

The following data results indicate the end of the caisson, located 65 meters (213 feet) away, to be in reasonable condition. An increased area of corrosion identified 32 to 35 meters (105 to 115 feet) down the caisson corresponding with the splash zone. Within the software an A-map can be produced instantaneously for all frequencies, providing valuable information about the circumferential extent to the technician. In this example, the operator could see that the worst area of corrosion in the splash zone was still within the acceptable limits.

This solution has been employed globally with great success. For example, BG International risers required an accurate assessment of conditions before entering service. The design of these risers called for them to be completely sealed inside caissons during fabrication. The risers found on the Neptune platform were assembled in bundles before insertion into caissons. These caisson tops are sealed with lids, each having an anchor flange that sits in a recess in the lid. Once sealed in the caissons, direct access to the risers is no longer possible. To overcome this, the risers needed to be inspected in their pristine state so that their condition could be compared with a digital twin and any degradation due to corrosion could be detected. It was found that transmission of ultrasound past the anchor flanges was possible and that the sprayed aluminum coating had no adverse effect on propagation. The pipe ends, 63 meters (207 feet) away, were readily detected and the possibility of detecting nine percent metal loss flaws in the splash zone, 18 to 20 meters (59 to 66 feet) from the transducers was demonstrated. To learn more about this inspection click here.

Similarly, risers in the South China sea were also inspected with this technology. The Thai State Oil Company PTTEP required 10 355-millimeter (14-inch) diameter risers on the Barykat oil production platform to be assessed. Test ranges of 20 meters (66 feet) were achieved down to the seabed, even with non-standard pipe diameters and the presence of clamps below the tool placement positions.

Barykat Platform Riser Inspection with GWT Solution

Barykat Platform Riser Inspection with GWT Solution

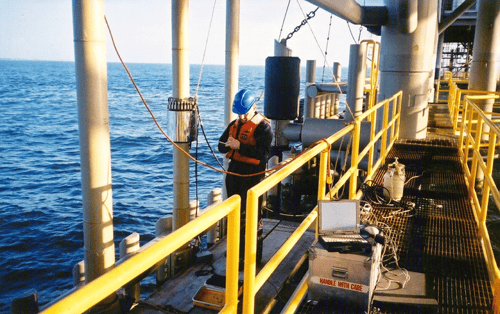

In another inspection, seven risers from an unmanned platform in Mobile Bay in the Gulf of Mexico underwent inspection. These included 150-, 200-, and 250-millimeter (6-, 8-, and 10-inch) pipes. With good access and all risers reachable from a walkway around the platform, all tests were successfully completed in a day including travel to and from shore.

Mobile Bay Platform Riser Inspection with GWT Solution

Mobile Bay Platform Riser Inspection with GWT Solution

When it comes to the examination of offshore and subsea assets like pipelines, risers, and caissons, Eddyfi Technologies rises to the most complex industry challenges. The proven Sonyks inspection solution combined with its data acquisition and analysis software offers the reliability and versatility operators should expect. Discuss your long-range ultrasonic testing requirements with us to keep you Beyond Current by getting in touch today.