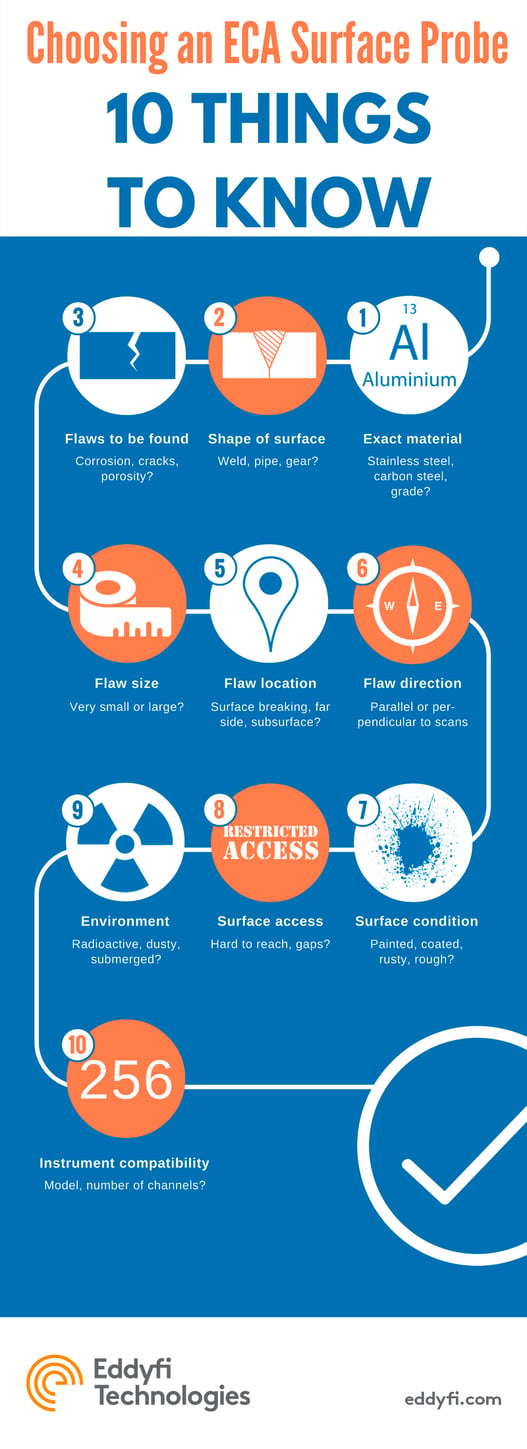

Back in 2014, we published a handy tool listing eight things you need to know before you use, choose, or buy an eddy current array (ECA) surface probe. We’re updating our tool, adding two things also considered essential, raising the total to 10! Read on to find out why they are essential.

(Cover photo credits: victorcamilo via photopin cc)

1. What type of material are you testing?

It’s not enough to know that it’s stainless steel, for example. Stainless steels all have their own very specific electromagnetic properties (e.g., 300-series stainless steel is non-ferromagnetic, 400-series is, and both contain exceptions). They can influence the configuration of the selected ECA surface probe and affect inspection results.

2. What’s the shape of the surface under test?

Completely flat? Concave? Convex? If so, what’s the bend radius? Does the surface have a unique or distinctive shape? Does it have an uneven geometry? Having CAD or clear pictures of the surface under test can make short work of determining the flexibility level of your surface probe.

3. What are the precise types of defects you’re looking for?

Looking for corrosion isn’t like trying to characterize cracking. Knowing whether you’ll be inspecting for pitting, stress-corrosion cracking (SCC), general corrosion, porosity, or something else helps choose the right inspection frequencies and topology — that is, how the coils are organized and activated inside the eddy current array surface probe.

4. Typically, how large are the defects you expect to find?

Knowing approximately how large the target defects are will help in choosing the appropriate coverage and resolution of the probe for your inspection needs. High-resolution ECA surface probes are excellent at detecting very small defects. But surface conditions and the total number of available channels of your test instrument may call for compromises that would make such a probe inadequate.

5. Where do you expect to find your defects?

Near the surface? On the far side of your surface? Somewhere in between? Knowing the approximate position of your target defects also helps pinpoint the correct operational frequencies and topology of your ECA surface probe for the right **penetration and coverage.

6. In what direction are your target defects?

If you’re looking to use ECA technology, the orientation of target defects in relation to the scan direction can prove crucial. Some topologies are not well suited to detecting cracks that run parallel to scans, while some are not well suited to detecting cracks running perpendicular to scans, for example.

7. What’s the condition of the surface under test?

Is the surface drenched in lubricant, lathered with paint, rusty, rough? Knowing this is essential because it’s going to dictate the type of contact interface of the ECA surface probe and its durability. Surface conditions also have an impact on the smallest defects that can be detected by any given ECT/ECA probe. Looking for very small defects on rough surfaces is all about compromises.

8. How hard is it to reach the surface under test?

Is the surface in a hard-to-reach location, high up, interspaced with gaps or supports? This can influence the shape of the ECA surface probe, make accessories such as poles or harnesses necessary, identify potential structural interference that must be taken into account, etc.

9. In what type of environment must the probe be used?

Is the probe to be used in a briny, radioactive, dusty, or controlled environment? Is the probe to be used near welding equipment, near magnetic sources, underwater? Knowing the type of environment helps to determine what types of mechanical designs are suited to you.

10. What test instrument are you using?

It’s important to know the model and available number of channels of your tester, because if it only has 32 available channels, you won’t be able to use a 256-channel ECA surface probe.

Although not immediately essential, the following information may also come in handy, because it can modify material properties and impart magnetic properties to materials that shouldn’t have them.

- Was the material under test mechanically, thermally, or chemically treated?

- How thick is the surface under test?

- Was the material cast or machined?

So, knowing the things above as precisely as possible makes shopping for that “perfect” probe easier for you or your inspection service provider. It also makes it considerably easier for your probe supplier to accurately assess whether you can use a standard ECA surface probe or if you need one that is [specifically tailored to your inspection needs. The good news: more than ever, standard ECA surface probes cover a wide range of conditions, so with the right information, it’s never been easier to shop for off-the-shelf probes.

Why not take a look at our line of ECA surface probes, as well as Ectane® and Reddy®?