With more than 50 years providing expert advice through our engineering services for the inspection and maintenance of your critical systems, Eddyfi Technologies remains committed to working with you hand in hand to discover the optimal and most efficient NDT solution to satisfy your particular inspection needs.

Details

Unlike other companies, our responsibilities don’t end with the engineering of products; we bring additional expertise with our field experience. We believe field experience is the best way to gain complete system understanding of how each part interacts with another: it’s simply the best way to gain insight and influence into our recommendations for your solutions. Our combined knowledge allows us to provide you with expert advice – the same high-level of trusted advice we’ve been giving our historical Eddyfi Technologies' customers since 1968.

We offer an array of defined solutions that are ready to be integrated into your NDT environment. They can incorporate several turnkey inspection systems or custom components to provide quick, cost-efficient solutions. These defined solutions may include everything from instrumentation, probes and sensors, to our own software. In addition, Eddyfi Technologies offers engineered-to-order (ETO) custom engineering solutions. All NDT solutions come with impressive track records of successful field use, saving development time of a one-off custom solution while providing the confidence of a proven implementation.

Custom Applications

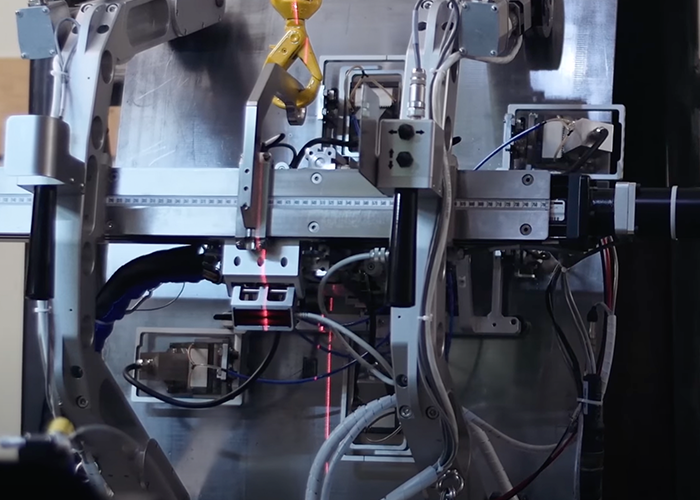

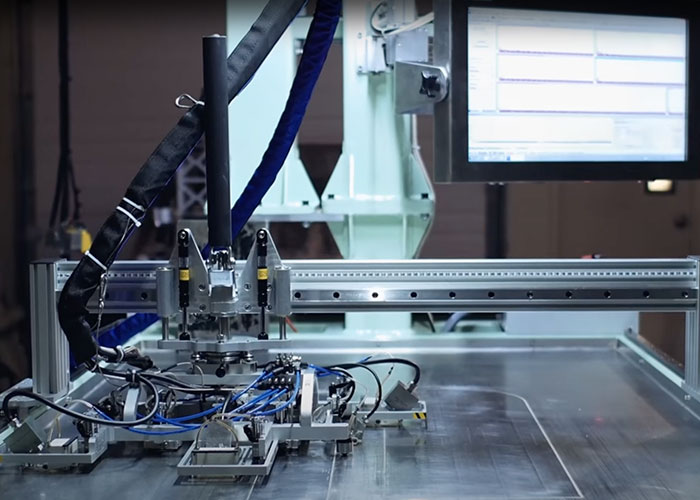

We provide customers with engineering services for designing custom solutions and inspection methods. We work closely with you to provide rapid evaluation of testing and to provide detailed technical proposals adapted to your specific needs. Our application specialists use their extensive phased array ultrasonic testing knowledge to help you discover your best phased array ultrasonic testing machine. We take into consideration your specific requirements and specific constraints. We also have the expertise and the experience to develop and manufacture custom systems and inspection methods that incorporate data acquisition systems, controls, probes, data analysis software and mechanical scanners.

Our custom applications use our UT generic equipment and software as well as these processes and tools:

- Technique development using our 3D Ray Tracing tools

- Probe and wedge design using our acoustic sound beam simulation tools

- Dedicated Mechanical customization

- Dedicated Software customization

- Hardware and firmware modification

- Manufacturing, integration, documentation, project management, factory and on-site acceptance test, start-up, training and on-site support.

Powered by intelligent PAUT instrument with TFM capabilities

The TOPAZ®64 is a portable 32 or 64 channel phased array ultrasonic testing (PAUT) instrument delivering faster, more reliable inspections. It intelligently combines the power of 32 or 64 active channels for PAUT applications with the most advanced full matrix capture (FMC), total focusing method (TFM), and plane wave imaging (PWI) capabilities.

Request a quote

All application consulting work is done in collaboration between you and our phased array ultrasonic testing, or PAUT, experts well versed in PAUT procedures and techniques. Besides custom solutions, we offer various generic application solutions including:

- Carbon Steel Weld Inspection

- Corrosion and Thickness Measurement using our PaintBrush2 solution

- Inspection of Austenitic and Dissimilar Metal Piping Welds

- Inspection of Heavy Forgings

- Rail UT Testing

- Composite Quality Inspection

- Inspection of Austenitic and Dissimilar Metals

- Turbine Blade Inspection

- Piping Weld Inspection

- Heavy Forging Inspection

- Boiler Tube Weld Inspection

- End Ring Inspection System with PAUT

- Turbine Rotor Bore Inspection System with UT and ECT

- Inspection of Composite Material

- Various UT and Mechanical Solutions for inspection of CANDU reactors.

System Integration

The members of our expert engineering team are skilled in helping you implement your Eddyfi Technologies equipment or application solution into your unique environment. Whether it’s the simple integration of a dedicated probe or probe holder to the complete integration of our automated inspection systems and software into your solution, you can count on our UT, ECT and mechanical application specialists for support. And with our Software Development Kit (SDK), you can efficiently integrate Eddyfi Technologies products into your inspection system. SDK is built for flexibility and customization, and it offers you the necessary tools for you to create your own components and modules. This allows you to bring unique and optimized solutions to your customers.

Ask an Expert