PaintBrush2 by Eddyfi Technologies. An evolution in the field of corrosion inspection for the detection of wall-thickness reductions due to corrosion or erosion.

Details

The PaintBrush2 sets a new market benchmark for corrosion mapping. This agile, patent-protected scanner is capable of inspecting both flat and curved surfaces, increasing inspection confidence by delivering 100% area coverage.

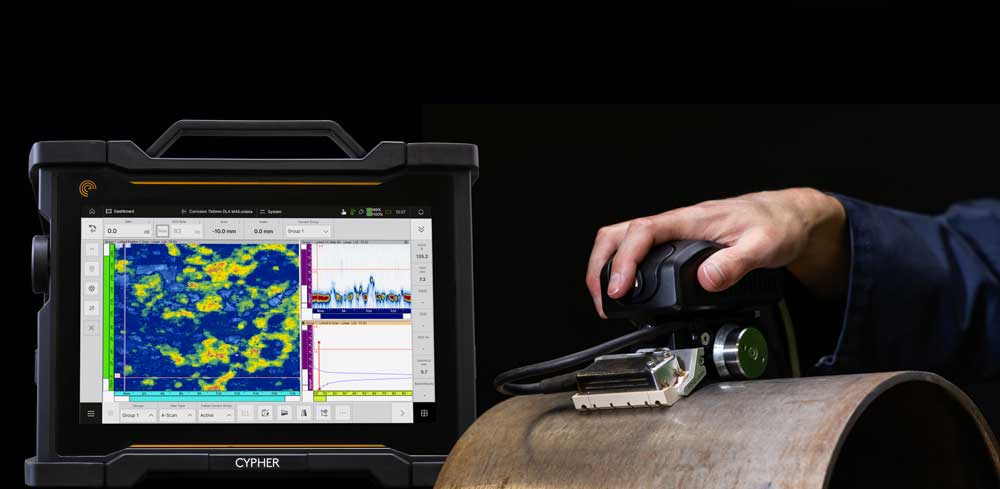

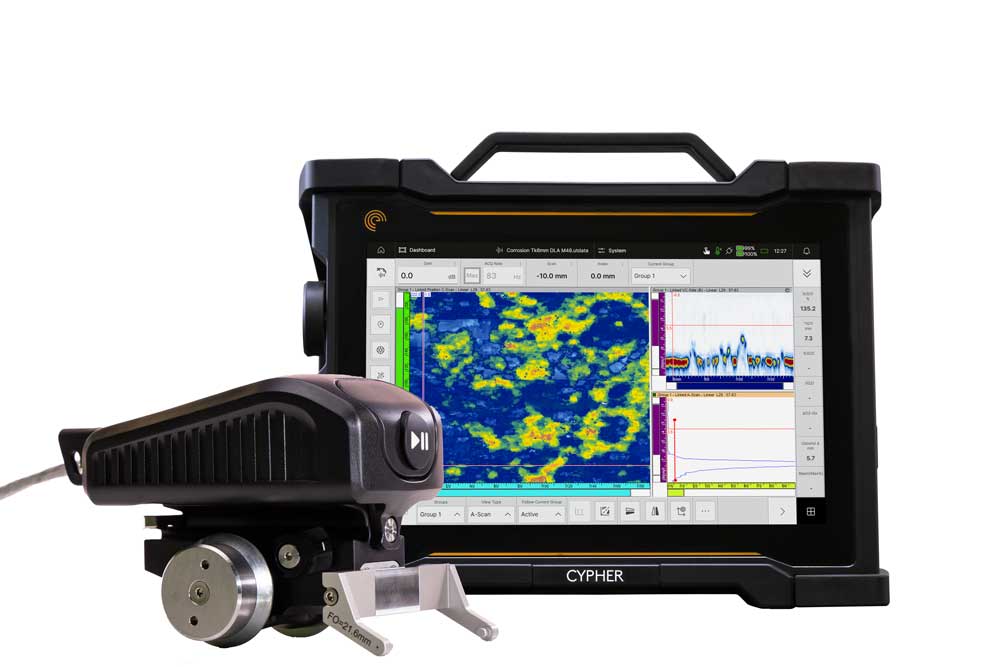

Its intuitive operation makes corrosion mapping quick and straightforward. When paired with the Cypher® ultrasonic instrument — which offers a wealth of corrosion-specific features — the PaintBrush2 becomes an even more powerful solution.

Engineered to meet a wide range of demanding inspection requirements, the PaintBrush2 pushes boundaries. The scanner is equipped with magnetic wheels that securely attach to metallic surfaces for easier use. For non-metallic surfaces, these wheels can be easily detached and replaced with dedicated non-magnetic wheels. Two encoded wheels track the scanner's position and orientation in real time, enabling operators to visually confirm coverage and avoid missed areas.

With an extensive operating temperature range, broad probe compatibility, and the freedom to collect data without grid constraints, the PaintBrush2 adapts seamlessly to diverse inspection scenarios. This makes it the most reliable solution available for corrosion and wall-thickness mapping.

Corrosion Mapping Without Boundaries

The PaintBrush2 is built for unmatched versatility, adapting effortlessly to plates, pipes, elbows, and more. Its compact, ergonomic design allows smooth scanning on curved or flat surfaces, with the ability to inspect pipes as small as 100 mm (4 in) in diameter and larger-diameter elbows.

With an extensive operating temperature range (-35 °C to 150 °C* / -31 °F to 302 °F*), freedom from grid constraints, and broad probe compatibility, PaintBrush2 is ready for nearly any inspection scenario.

Supporting advanced techniques including TFM, PWI, and PAUT, the scanner is ideally suited for general corrosion and composite inspections, HTHA, and HIC evaluations.

Compatible probes include the Dual Linear Array, A11 (0L), A12 (0L), and NW1, ensuring inspectors can tackle diverse applications with confidence.

*Note: Intermittent operation, maximum duration of 25 min. at 150°C (302°F)

Optimum POD: Find corrosion pitting

Detects small wall-thickness losses equivalent to 1.6 mm (0.06 in) round-bottom holes, with coverage ranging from 2 mm (0.07 in) to 25 mm (1 in). The solution offers a high probability of detection and, with extended probe compatibility, meets the specific requirements of various inspection scenarios.

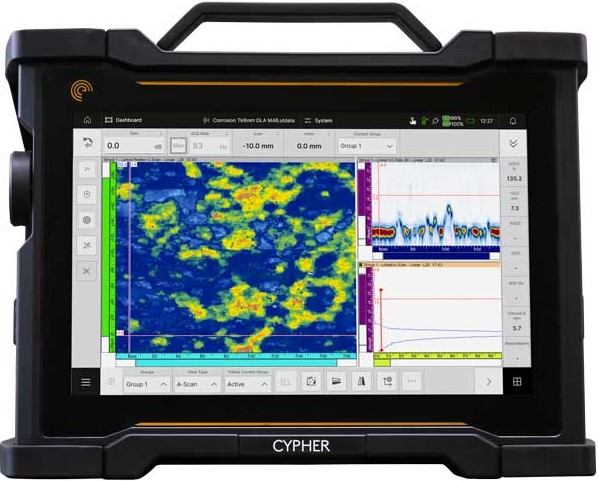

Powered by Advanced Analysis

PaintBrush2 pairs seamlessly with the Cypher instrument, bringing real-time acquisition power directly to the inspection. Seeing the location of the probe and data in real time during inspection ensures that the inspection process is performed well, covering the entire target area. Seeing the indications in real time allows you to properly assess the inspection process.

Confidence in Every Scan

- Real-time visualization of probe position and data ensures full area coverage

- Easy to use, requiring minimal training while delivering high performance

- Clear imaging & stitching make it simple to track part condition and evolution

With the PC companion software, inspectors gain access to a powerful suite of advanced analysis tools:

- Real-time and post-processing analysis

- Up to 4 gates and 5-gate detection modes (First Peak/Flank, Max Peak/Flank, Last Peak)

- Detection modes: First Crossing, Maximum, NR Crossing/Max

In addition, UV3 advanced analysis software provides enhanced data handling and reporting capabilities:

- Aberrant point removal

- C-Scan merge & stitching

- Corrosion-specific statistical analysis

- Assisted Analysis — automatically selects and reports indications based on predefined criteria

3D Plotting

Corrosion is easily identifiable with UltraVision 3; get 3D plotting for outstanding rendering of corrosion data on specimen parts. The tool can specify the depth of the corrosion, therefore, you know when action must be taken.

Together, PaintBrush2 and Cypher deliver fast, accurate, and reliable corrosion mapping across a wide range of applications.

Specifications

Scanner

83.6 mm x 95.3 mm x 149.9 mm (3.29 in. x 3.75 in. x 5.90 in.)

950g (2.09 lb) without cable

5m (16.4ft) & 10m (32.8ft)

+5V ± 10% @ 200mA

Pause and restart acquisition or if held for 3 seconds, resets encoder positions to zero (0)

Inspection Diameters and Positioning

101.6 mm (4.0 in) Horizontal and vertical

1219.2 mm (48 in) or Flat

±1.4 mm/1000.0 mm typ.

Environmental

-35°C to 150°C (-31°F to 302°F) Note: Intermittent operation, maximum duration of 25 min. at 150°C (302°F) with ambient temperature at 22°C (72°F).

-35°C to 75°C (-4°F to 167°F) with relative humidity up to 95% non-condensing

-40°C to 75°C (-40°F to 167°F)

Designed for IP65 (pollution degree 2)

CE compliant