The integrity of pipelines relies on the integrity of its inspection equipment. Eddyfi Technologies’ proven solutions offer accurate, reliable and repeatable data in real time. In-service pipeline inspection promotes time and cost efficiencies, ensures environment and human safety, and endorses long-term reliable performance of pipe infrastructure.

Details

Pipelines are used around the world to transport gas and oil every day and are without a doubt the safest way to transport such commodities. Prone to damage by corrosion, cracking and potential design flaws, pipelines require regular inspection to help ensure structural integrity and regulation compliance as well as verify the remaining useful life of infrastructure. Examining pipelines typically involves an inline inspection (ILI) using pigs or remotely operated robotic crawlers to locate areas of concern so that further assessment can be performed using Non-Destructive Testing (NDT) tools on the excavated pipeline (where previously buried). Eddyfi Technologies’ advanced solutions assist with improving practical planning, reducing operational and safety risks, and increasing profitability for pipeline owners internationally.

Pipeline inspections include, but are not limited to, NDT of difficult and unpiggable pipelines, transmission and distribution lines. Our tools help identify areas containing external corrosion, internal corrosion, stress corrosion cracking and other defects that impact the integrity of the pipeline. This includes pipe welds, walls, and support contact areas. With a baseline condition from inspection, operators and owners can make informed decisions for immediate renewal and preventative maintenance, allowing them to effectively manage their assets through re-inspection and future capital planning.

Eddyfi Technologies offers multiple NDT options for pipeline inspection; no single method can do everything in an inspection. Depending on your specific data collection requirements, you may opt for one or multiple pipeline inspection solutions.

Long-Range Ultrasonic Testing

A high-speed solution, Sonyks performs advanced Long-Range Ultrasonic Testing (LRUT) which involves surveying long lengths of pipeline from a single test point. Unlike traditional UT, LRUT generates an axial UT wave that propagates along the pipe and requires no couplant between transducers and the surface being inspected – making the Sonyks one of the fastest NDT tools for flaw detection during pipeline inspection. This system was the first commercial product offering all the benefits of conventional guided wave screening technology with the added feature of focusing sound energy into specific regions of pipelines to measure the distribution of corrosion around the circumference at a specific distance. This is particularly valuable to skilled inspectors who need to make fitness-for-service (FFS) engineering assessments. Pipelines can be tested in service, avoiding the need to shut down and stop production for inspection. A wide range of pipe sizes can be inspected, from 51 to 1,219 millimeters (2 – 48 inches) nominal diameters.

Phased Array Ultrasonic Testing

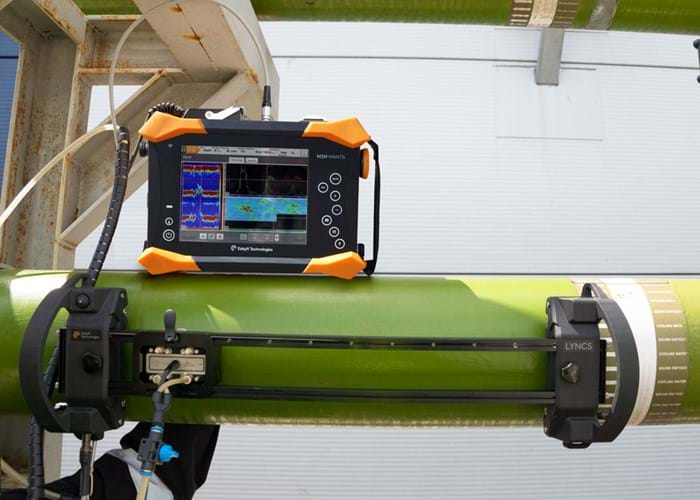

Phased Array Ultrasonic Testing (PAUT) is another advanced UT solution for the accurate detection and measurement of discontinuities within the specified inspection volume from the outside diameter surface; this includes pipeline systems susceptible to stress corrosion cracking. Industry leading M2M Gekko® and M2M Mantis™ systems are high resolution portable flaw detectors that employ PAUT, time-of-flight diffraction (TOFD) and Total Focusing Method (TFM) for these detailed assessments quickly. While radiography and UT are both commonly employed for pipeline inspection, PAUT offers the advantage of no radiation, risk, or additional licensing required.

With automated corrosion mapping increasingly becoming an integral part of NDT inspections, Eddyfi Technologies’ RMS PA phased array inspection solution increases productivity without sacrificing resolution and Probability of Detection (PoD). For tight spaces Eddyfi offers the manual LYNCS scanner, Its extremely low profile and lightweight design is ideally suited to vessel and pipework in tight spaces, making it the most suitable option for rope access deployment and heavily congested pipework. For tight spaces, we would recommend the LYNCS manual scanner. Its low profile and lightweight design is ideal for heavily congested pipework. It is reliably used for detection of general corrosion and erosion, Microbiological Induced Corrosion (MIC), Hydrogen Blistering (HB) and laminations.

Eddy Current Array

When it comes to pipeline crack detection, Magnetic Particle Inspection (MPI) is often used effectively but comes with known drawbacks: surface preparation is required, manual length sizing, no depth sizing, and lack of digital data. Eddy Current Array (ECA), a digital electromagnetic NDT technique, has proven to be a more efficient alternative. The Eddyfi Spyne™ is an adaptable surface ECA screening tool designed specifically to maximize productivity for the detection of stress-corrosion cracking (SCC), subsurface defects, and pitting in pipelines. With a higher PoD than MPI, its ultrafast capabilities pave the way to unprecedented efficiency. The Spyne works in combination with Reddy®, a rugged portable ECA instrument with a large multi-touch screen displaying the color-coded maps (C-scans) generated by the tool.

Remote Visual Inspection

In addition to the advanced NDT inspection tools mentioned, Eddyfi Technologies offers a range of robust pipeline inspection crawlers for the Remote Visual Inspection (RVI) and remote-controlled operations in long pipelines as small as 50 millimeters (2 inches). Inuktun Versatrax™ pipeline inspection crawlers are also the ideal robotic transporter for Eddyfi Technologies’ probes and sensors for comprehensive structural integrity assessment of pipelines across all industries.

The integrity of pipelines relies on the integrity of its inspection equipment. Eddyfi Technologies’ proven solutions offer accurate, reliable and repeatable data in real time. In-service inspections promote time and cost efficiencies, ensure environment and human safety, and endorse long-term reliable performance of pipe infrastructure.

-01-01.jpg?preset=details-img-fb)