Remote-Field Testing (RFT)

Remote-field testing (RFT) is a non-destructive electromagnetic testing technique mainly used to find defects in steel pipes and tubes.

Details

How it Works

RFT probes use one or several transmitter coils positioned two tube diameters apart from the receiver coil. The magnetic field created by the transmitter coil travels through and out of the tube wall, radially and axially, towards the receiver. The magnetic field must travel through the tube wall again to reach the receiver. This is called through-transmission and is what defines RFT. Through-transmission allows external and internal defects to be detected with equal sensitivity.

Two coupling paths exist between the transmitters and receivers. The direct path, inside the tube, is rapidly attenuated by circumferential eddy currents induced in the tube’s wall. The indirect coupling path originates in the transmitter’s magnetic field that diffuses radially outward through the wall. At the outer wall, the field spreads rapidly along the tube with little attenuation and re-diffuse back through the pipe wall and are the dominant field inside the tube at the receiver. Anomalies anywhere in the indirect path cause changes in the magnitude and phase of the received signal, and can therefore be used to detect defects.

Ask an ExpertBenefits

RFT has several benefits over other electromagnetic testing techniques:

- Suitable for ferromagnetic materials

- Equal sensitivity at the inner and outer surfaces

- Highly sensitive to wall thickness variations

- Can be used with lesser fill factors than ECT

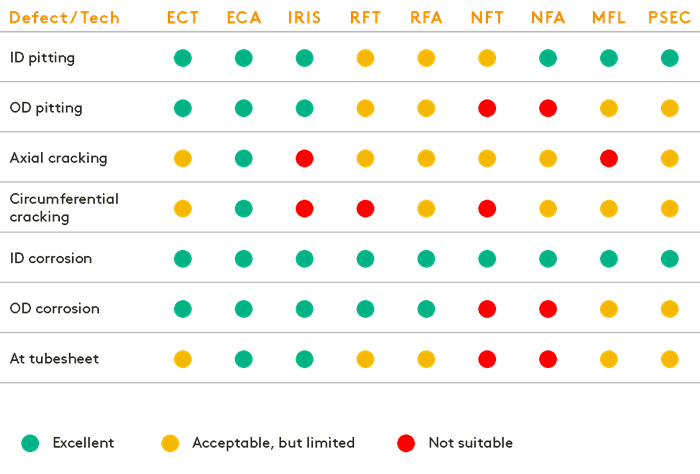

Detection Capabilities According to Defect Type in Tubing

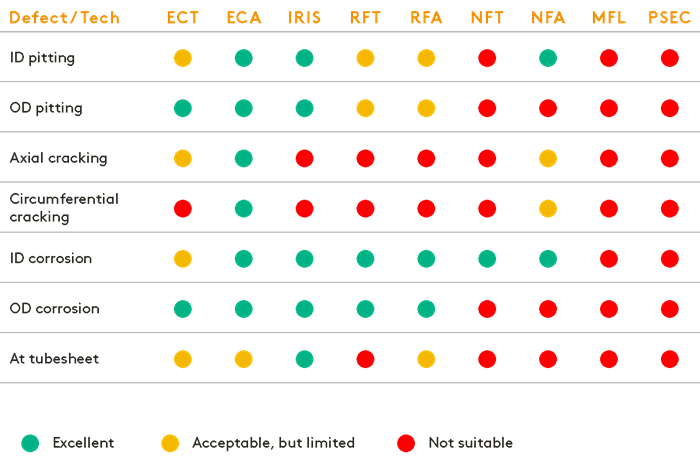

Sizing Capabilities According to Defect Type in Tubing

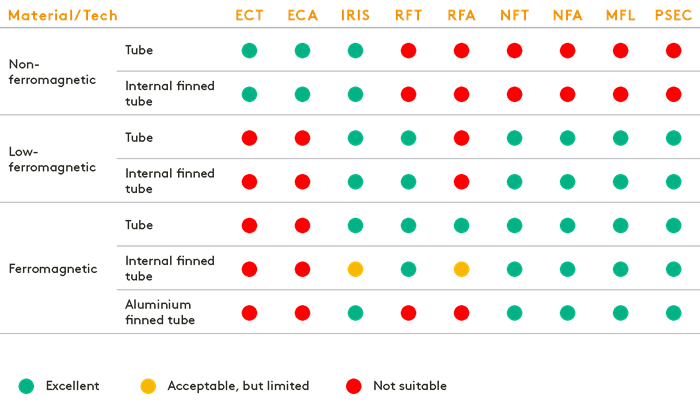

Suitability According to Tubing Material

Learn more