Phased Array Corrosion Mapping

Complete turnkey PAUT solution from instruments to scanners and probes.

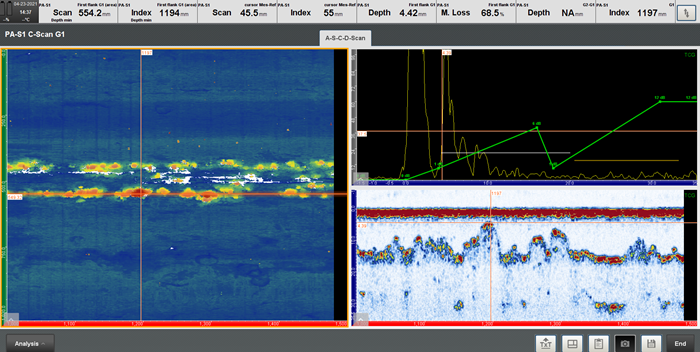

Ultrasonic corrosion mapping is a non-intrusive inspection technique that maps material thickness using ultrasonics. Variations in material thickness due to corrosion can be identified and graphically portrayed as an easy to interpret picture.

Eddyfi Technologies offers a complete solution with advanced phased array instruments, a range of automated and manual scanners, and a full range of probes and wedges.

Details

Phased Array Corrosion Mapping

Recognition from various inspection bodies and asset integrity engineers has resulted in phased array ultrasonic testing (PAUT) becoming the preferred technique for corrosion mapping.

PAUT is widely used for the in-service detection and characterization of corrosion in pipes, tanks, vessels, and other critical assets. Due to a larger footprint, PAUT probes can cover a larger surface at higher speeds leading to a significant time reduction and enhanced resolution.

Eddyfi Solution

Eddyfi Technologies offers a complete turn-key solution with advanced phased array instruments, a range of automated / semi-automated scanners and a full range of probes and wedges.

- Complete turnkey package

- Integrated scanner control built into the software

- Onboard electronics for all semi-auto scanners

- Combination of contact or immersion methods

- Advanced application software features

- Remote analysis via TeamViewer

- Range of modular scanners

Applications

- Pressure vessels

- Storage tanks

- Pipelines

- Spheres

- Restricted access areas

- Ship hulls and other marine vessels

- Other critical assets

Instruments

Gekko®

The powerful Gekko comes with conventional UT, TOFD, and all beam-forming phased array UT techniques for single-beam and multi-group inspection, plus its 3-encoded axis capabilities make the Gekko ready for any challenging inspection.

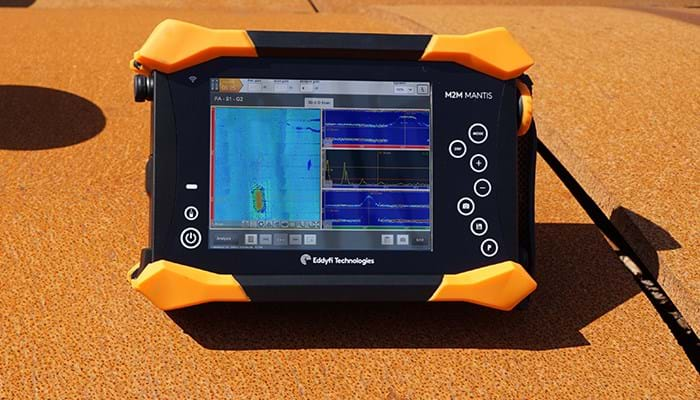

MantisTM

Designed for corrosion mapping, the portable Mantis system is a light and economical version of Gekko using the same technologies and software interface, Capture™.

TOPAZ®64

The ultra-intelligent TOPAZ64, a portable 64-channel phased array ultrasonic testing (PAUT) instrument delivering faster, more reliable inspections.

Scanners

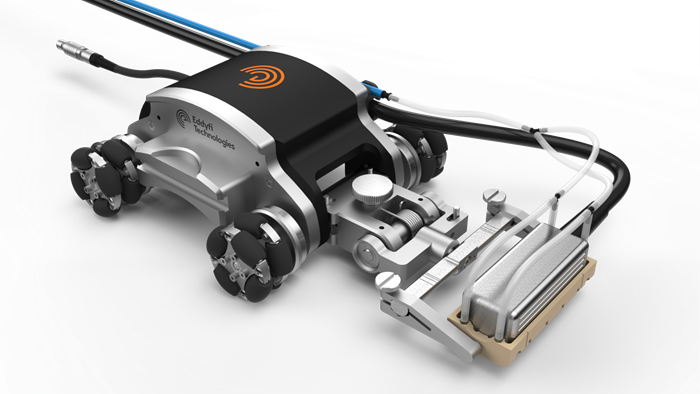

Automated Solution

The automated, robust, field-proven robotic scanner has been successfully deployed on various assets such as storage tanks, pressure vessels, pipelines, and other critical infrastructure. Ideal for extensive area inspections, difficult-to-reach assets or surfaces at an elevated temperature.

- Remote access up to 30m (98.4ft)

- Modular arrangement suiting various applications

- Battery operated

LYNCSTM

A modular scanner with interchangeable bar lengths to suit inspection requirements. LYNCS is a versatile scanner with onboard scan controls is ideal for corrosion mapping of pipes from 100mm (4in) diameter up to flat plate. Due to its lightweight and ease of use, the scanner is perfect for rope access inspections.

- Easily switch from corrosion mapping to weld inspection.

- Low profile for tightly spaced pipe racks (110mm/4.3in).

- Magnetic wheel with brakes to stop slippage.

NDT Sweeper

The handheld NDT sweeper is a highly versatile semi-automated 2D encoded scanner which can virtually replace multiple specialized scanners due to its ability to perform corrosion mapping and weld inspections. The scanner is the perfect solution for the inspection of complex geometry components including curved surfaces, flat plate, pipelines, and restricted access areas.

Thanks to its small, lightweight, and ergonomic design, NDT Sweeper can easily scan in many difficult-to-reach areas eliminating the need to deploy an automatic scanner in those situations. Unlike wheel probes, both axes are encoded so there is no need to draw an index line on the specimen when scanning.

- Two integrated encoders; 2D scanning precision

- Highly versatile tool

- Perfect complement to Automated solution for maximized coverage

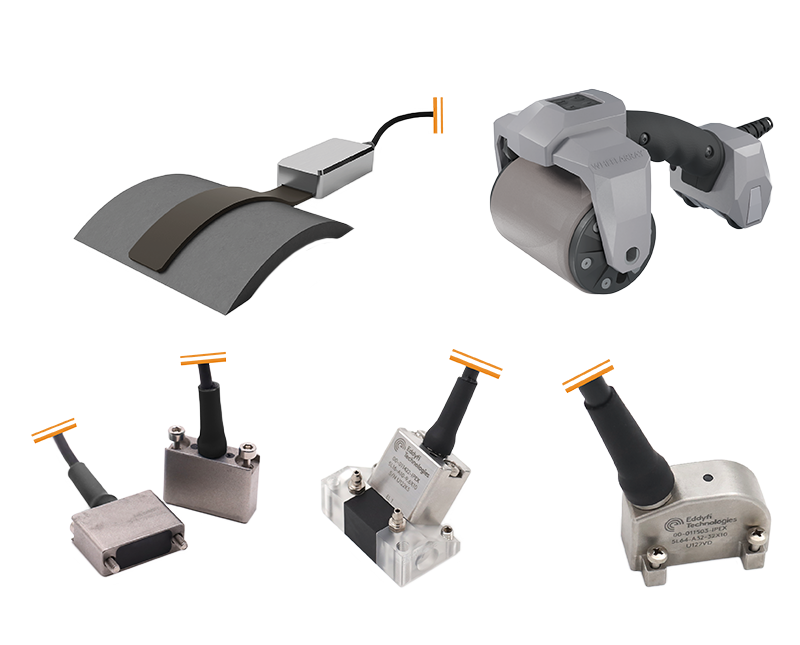

Probes and Accessories

The phased array configurations comes with options for contact and immersion type Inspections. The immersion type offers a unique water box to create a water-column concept that eliminates the need for a wedge, thus providing the benefits of improved signal consistency, accuracy, and limited dead zone. This concept offers enhanced surface conformity and improved coupling. When a contact test method is preferred, Eddyfi’s Dual Linear Array probe provides improved near surface resolution, allowing detection of defects as low as 1mm (0.04 in.) below the surface. Both methods deliver high probability of detection (POD) of critical defects when compared to conventional ultrasonic methods.