We offer inspection solutions for homeland security, intelligence reconnaissance, border and transportation security, counter terrorism, critical infrastructure protection and emergency response. Ruggedly built, portable, and adaptable to specific requirements, our proven inspection tools are ready to answer the most challenging military and security demands.

Details

Whether part of a continuous monitoring program or under emergency response, Eddyfi Technologies’ advanced NDT solutions help quickly identify and assess situations that put people, places, or national security at risk. As a supplier and strategic business partner with militaries and numerous police and fire departments, our robust technology has been utilized by security and defense groups worldwide.

Continued evolution of non-destructive testing technologies increase the ability to detect and characterize the defects that threaten the integrity of capital assets found on military installations, the facilities themselves, and vehicles while remotely operated robotics contribute to otherwise dangerous investigation and retrieval operations. Like any NDT technique, they each feature particular benefits and drawbacks thus multiple methods may be complementary, if not a key advantage for Beyond Current assessments. Read on for specific applications, and contact us to discuss your specific security and defense inspection requirements.

Storage Tank Inspection

Storage tanks are common to the security and defense sector, typically containing aviation or ship fuel products but also standard vehicle fuel. These tanks may be above ground, buried, or semi-buried horizontal or vertical cylinders. The FloormapX and Handscan, Scorpion2™, R-Scan and RMS with R-Scan Array offer inspection of these aviation and shipyard tanks, employing both MFL and ultrasonic testing for corrosion mapping and thickness measurements of the tank shell and roof. With portable phased array UT (PAUT) instruments —like the Mantis™ and Gekko®— operators can perform corrosion mapping inspections with confidence, combining high Probability of Detection (PoD) of pitting and other corroded areas with high productivity. Often the underground tanks will have an external concrete lining so besides being underground without excavation the inspection would need to be carried out internally. Where the cylinder diameter allows, the RMS with R-Scan Array provides corrosion maps of the externals looking for exterior corrosion from inside. The MaggHD™ miniature magnetic crawler used for remote visual inspection (RVI) may also be considered for buried tanks, alleviating the associated risks with manned confined space entry.

Data Center Chiller HVAC Inspection

Maintaining uptime with optimized cooling system assessments is essential for buildings and data centers used by the military and security sector. Water-cooled chillers found in the HVAC system of large buildings can efficiently be inspected by the Eddyfi Reddy® AC solution.

Request a quote

.png)

Armored Vehicle and Artillery Inspection

When it comes to NDT of vehicles on land, in air or at sea, we offer a range of solutions. For example, Eddy Current Array (ECA) has been used to inspect different artillery components. A scanner and array probe offer superior detection of small cracks in these tubes - effectively replacing conventional Magnetic Particle Testing (MPT or MT) which is a cumbersome process that heavily relies on operator efficiency. MT has traditionally been employed for the inspection of armored vehicle components prior to assembly. This includes looking for cracks in bended and formed metal sheets. While the sheet metal is not high value per se, inspecting it prior to assembly is a high value operation. ECA performed with the Eddyfi Ectane® 2 or Reddy® Surface electromagnetic NDT systems allow better detection and sizing of cracks. Past production, PAUT and Alternating Current Field Measurement (ACFM®) are both extensively used during routine maintenance work on armored vehicles. The TSC Amigo® 2 instrument accurately detects and sizes surface-breaking cracks through paint and coatings.

Aircraft Inspection

Just like commercial aerospace assets, military airbases have the same requirements for aircraft non-destructive evaluation (NDE). This includes the examination of dovetails and blade roots found in aircraft engines. ECA technology has been employed for the efficient inspection of gas turbine dovetails, locating minute cracking and extending the life of aging equipment. A one-pass scan enables faster non-destructive inspection (NDI) of the complex geometry, reducing user dependency compared to conventional techniques. ECA has also replaced single channel ET probes for the inspection of cracks around rivets.

Ship Inspection

Various components of naval ships require regular inspection. On board, analysis with the Ectane 2 and Eddyfi tubing probes can be done on water cooler chillers, lube oil coolers and others. Learn more about accelerating tubing inspection applications here. Military ships are susceptible to scab corrosion on carbon steel pipes, particularly the fuel oil transfer lines. The Eddyfi Lyft® instrument and Pulsed Eddy Current Array (PECA) high resolution probe offer the most reliable option for the inspection of scab corrosion, enabling integrity engineers to collect all the information required for strong risk management. Ship deck inspection, also referred to as deck plate inspection or deck surveys, is necessary to locate corrosion otherwise hidden. This can be performed without needing to remove flooring material, mitigating the cost of not knowing in ships. Pulsed Eddy Current (PEC) has demonstrated its value for detecting corrosion in ship hulls.

Ask an Expert

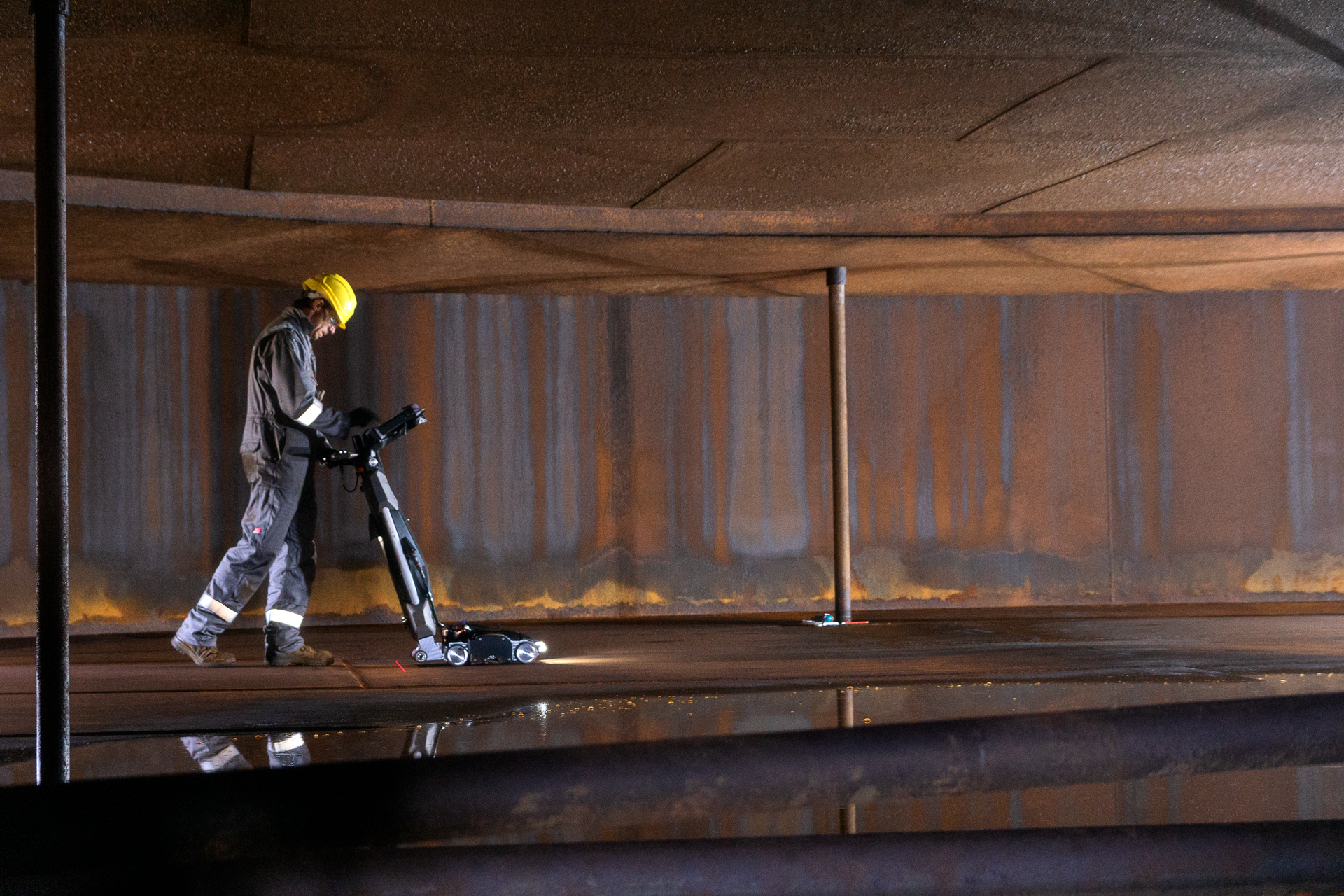

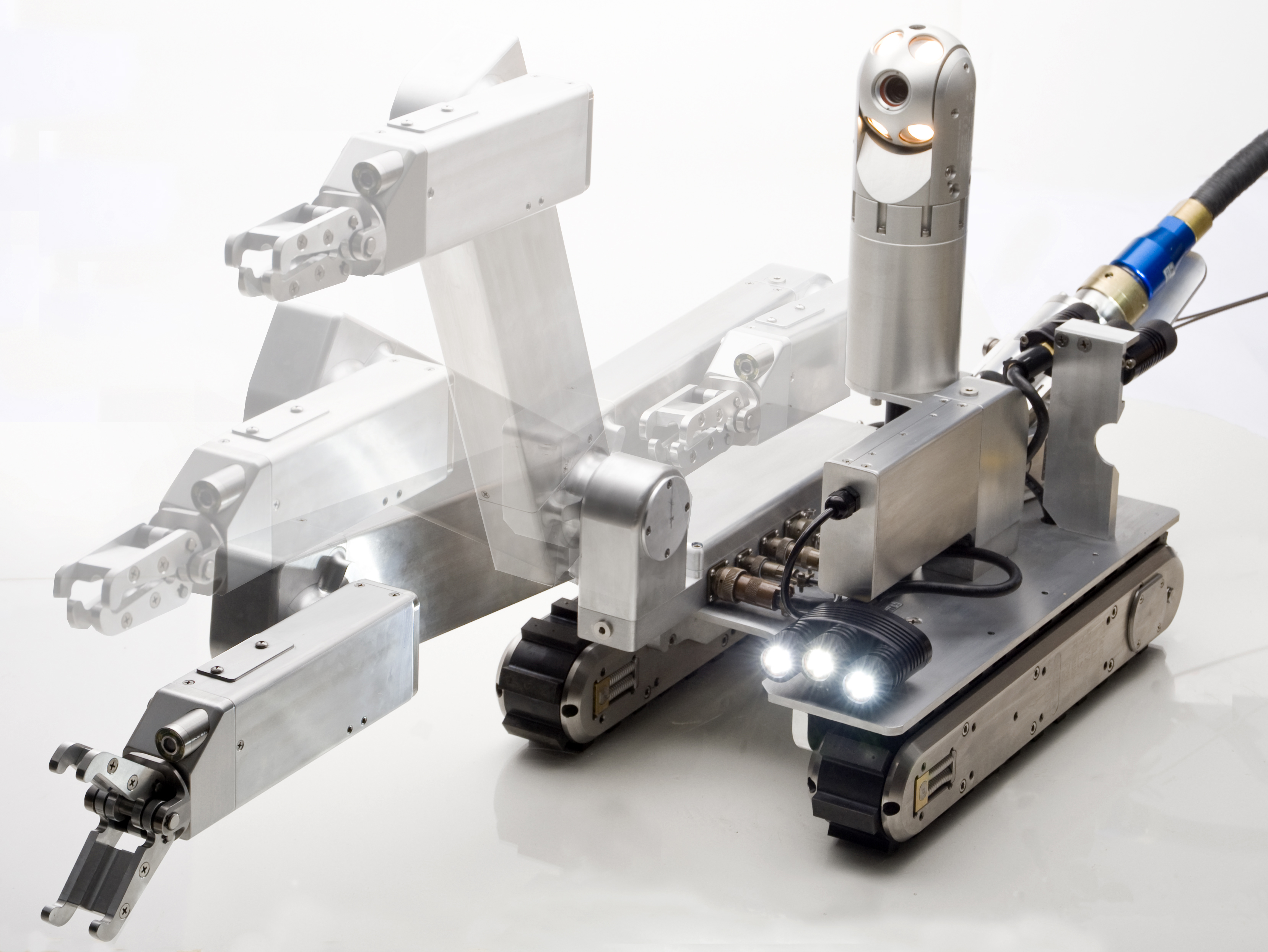

Automating this inspection with an Inuktun crawler offers obvious cost and time saving benefits; an inspection robot can be used to look for parasitic devices on ship hulls at the same time. Inuktun crawlers can be remotely deployed to visually search for weapons, people or contraband in hidden areas, shipping containers and storage tanks. The RMS and Scorpion crawlers are the ideal solution for remote UT of military ship hulls and deck plates as well as flight and hanger decks. Finally, Eddyfi Technologies enables detection of corrosion under the rubber sheeting used to prevent radar echoes in submarines. Without having to remove acoustic or anechoic tiles, our electromagnetic solution based on a unique ECA probe with special coil design accommodates the presence of tiles and provides indications for corrosion, pitting and tile disbanding quickly.

Robotic Crawlers for Remote Operations

The Inuktun Versatrax 150™ pipe inspection crawler has a proven history of deployment for examining bunkers and cross border tunnels.

Similarly, an OnSpec Custom Solution called the Versatrax 450™ was designed for accessing potentially hazardous tunnels, able to handle any suspicious packages with its articulating manipulator arm featuring an integrated camera for improved dexterity. Inuktun robots have assisted in emergency responses such as the September 11 terror attack, Hurricane Katrina, the Crandall Canyon mine collapse, and Thai cave rescue.

Count on Eddyfi Technologies to deliver the trusted solutions for public safety, intelligence surveillance and reconnaissance, transportation and border security, counter terrorism, protection of critical infrastructure and emergency management. Get in touch to discuss our Beyond Current military and security inspection solutions today.