Remote-Field Array (RFA)

Leveraging Remote-Field testing’s (RFT) low fill factor requirement, equal sensitivity to both external and internal defects as well as faster than IRIS pulling speed, RFA offers greater insight on the defect morphology and greater sensitivity to external features thanks to an array of coils that produce high-resolution C-scan imaging.

Details

How it Works

The RFA probe includes two transmitting coils placed on either side of the probe head. Near the center of the probe body are two coils wound around the probe body that produce a conventional absolute and differential signal. In addition to these elements, which give signals remarkably similar to those obtained with an RFT probe, two rows of small sensors (coils) produce high resolution absolute and differential array channels.

The RFA probe leverages the conventional “transmit-receiver” capabilities of the Remote-Field technology. The magnetic field created by the transmitter coil travels through and out of the tube wall, radially and axially, towards the receiver. The magnetic field must travel through the tube wall again to reach the receiver. This is called through-transmission and is what defines RFT.

Ask an ExpertC-Scan imaging

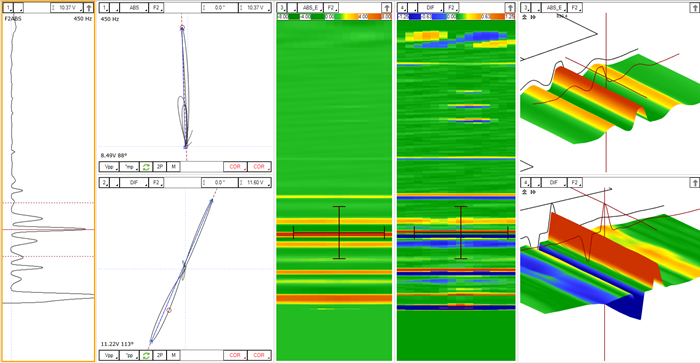

To create high-resolution C-scan imaging, coils were developed and added to the probe head. They are aligned on two separate rows in a staggered pattern. To create the ABS C-scan, the signals received from all individual array coils on one row are combined. To create the DIF C-scan, both rows are obtained by subtracting the signals of row 1 from row 2. As with conventional channels, the absolute array is typically used to analyze large volumetric defects, such as taper defects and wear scars, and the differential array is used to analyze smaller defects such as pits and cracks.

Low-frequency multiplexing

To achieve such a resolution and maintain the same pulling speed as RFT probe, a low-frequency multiplexer was developed and patent acceptance is pending. Using a low excitation frequency, the RFA probe time-division multiplexing technology works by enabling a certain number of coils all at once and then sequentially switching to the following coils until the whole tube circumference is covered.

Benefits

The RFA probe can be used at the same pulling speed and fill factor as RFT probes. It also offers several benefits over conventional RFT technique:

- Real-time C-scan imaging that offers greater insight on defect morphology, leading to a better sizing curve selection by the analyst.

- Reduced blind zones and improved detectability near support plates and tubesheets

- New centering devices leading to more consistent signal response and improved Probability of Detection (PoD) on smaller indications.

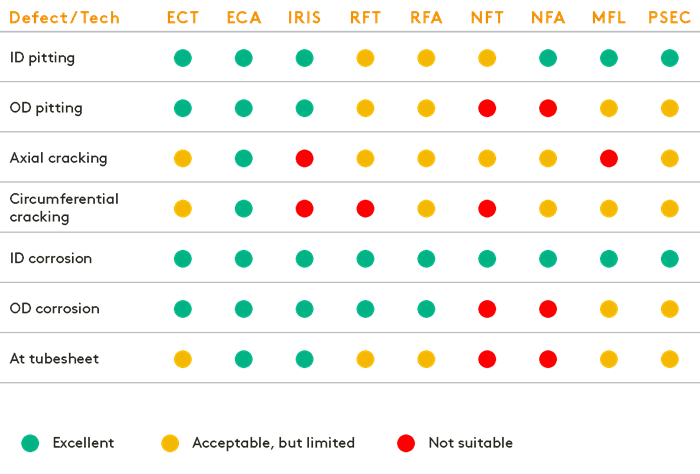

Detection Capabilities According to Defect Type in Tubing

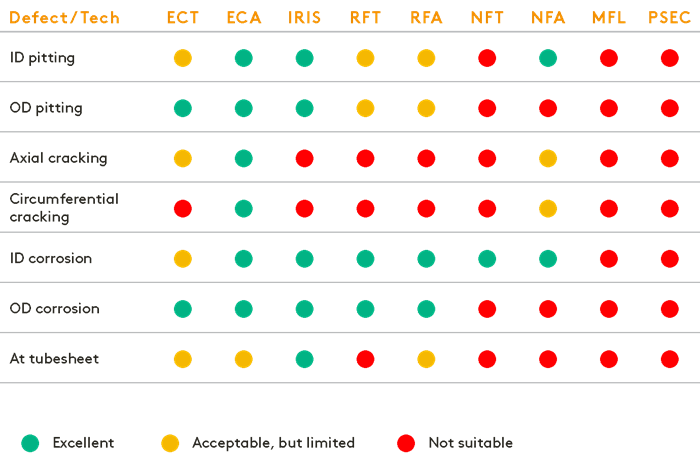

Sizing Capabilities According to Defect Type in Tubing

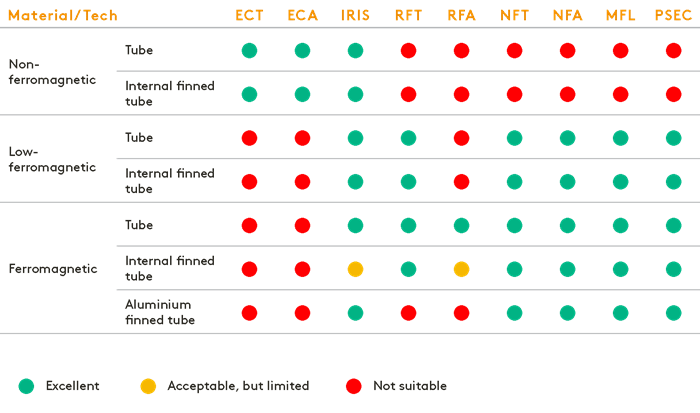

Suitability According to Tubing Material

Learn more