Artificial Intelligence (AI)

Artificial Intelligence Detection Capabilities for Eddy Current Testing (ECT) Tubing Inspection

Details

Key Features

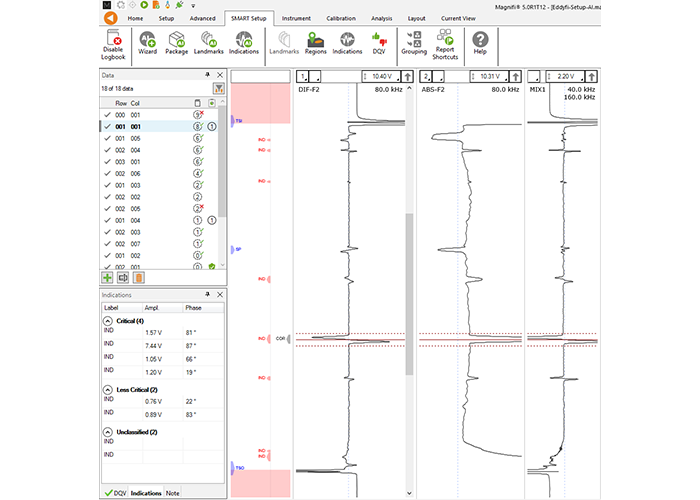

- Reduce the chances of leaving a significant indication behind with automatic AI detection.

- Automatically find and position tubesheets and support plates with high accuracy

- Fast, patent pending data processing that returns AI findings in less than one second

- Analyst remains in full control; AI findings are suggestions of potential indications and the analyst is responsible to report the relevant indications.

The Technology

Artificial Intelligence (AI) made major breakthroughs in the past decades and multiple industries now rely on these new technologies to revolutionize various complex tasks and help workers improve their efficiency. Among various technologies tagged “artificial intelligence”, a subset is referred to as “machine learning”.

A machine learning model is nothing more than a mathematical model representing the relationship between a set of input parameters and an output result. The particularity of machine learning is that the model is “learned” from experimental data using an automatic learning process and statistical methods.

The learning process may be implemented in many ways, but the most common strategy is called “supervised learning” which requires the creation of a training database containing many examples of the relationship between the machine learning model inputs and the expected output results. During the “learning” or “training” process, the machine learning model parameters are adjusted or optimized to reproduce the inputs-output relationship on the examples of the training database. If the database is carefully crafted and the model is chosen properly, one may expect that the training model will not only be able to accurately reproduce the inputs-output relationship on the training database, but also produce correct results on new data that is not part of the database: the model is said to “generalize” to new data.

The selection of the training data is very important to ensure that the training process delivers a model with good generalization properties. In particular, the database must be representative of the expected data in real life scenarios. For example, if we want to develop a model to recognize cars in a picture, we need to build a database with pictures of all common car shapes, such as 4-door sedans, pick-up trucks, and SUVs. If only sedans are included in the database, the model will not be able to generalize to the other car shapes. To correct this situation, more pick-ups and SUV examples must be added to the database, and the model must be retrained. This is typically a continuous process; if the retrained model has difficulty on other car shapes, new examples are added to the training dataset and the model is retrained again, and so on. For these reasons, machine learning models are expected to improve over time if the training database is continuously expanded with new, well-chosen examples.

Capabilities

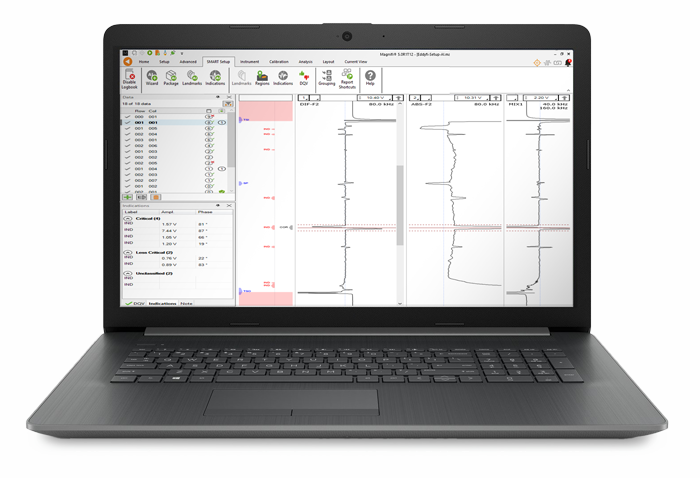

For ECT tubing inspection data, the end result is a patent pending detection process that automatically finds, positions, and marks the beginning and end of any relevant indications. As soon as data collection is complete or the data file loaded, the AI neural networks process the signal and return the landmarks and potential location of any indications within the Magnifi software interface. This process is optimized to be executed in under one second to address the industry’s target of having inspection results as fast as possible.

Artificial intelligence algorithms are developed to continuously adapt and evolve to address more situations. The way it was designed in Magnifi software, for example, is that its capabilities will always be combined with a Magnifi version and release number. However, it is important to note that users are not responsible for the model training process. This training process is meticulously managed by our AI team (yes, composed of real humans) using carefully selected and tagged data.

Requirements and Limitations

For optimal detection capabilities, users must follow the ASME guidelines on calibration and inspection parameters such as proper calibration, frequency selection, and pull speed.

For the inspection equipment, we recommend using Eddyfi bobbin probes to ensure proper compatibility. As for data analysis, Magnifi 3.X and 4.X files can be processed with Magnifi 5.X AI neural networks.

For detailed capabilities and limitations of specific detection modules, please refer to the AI detection module software release notes found here.

Ready to futureproof your inspection operations with the helping hand of AI? Ask an expert how to best implement tomorrow’s technology today and stay Beyond Current.