Bolts and Threads Inspections

Eddyfi Technologies for Bolts and Threads Inspection Applications

Bolts and threads are critical structural components that require regular integrity assessment. Whether verifying manufacturing or determining fitness for service, bolt and thread inspection is necessary for compliance with safety regulations.

Details

Bolts and threads are critical structural components that require regular integrity assessment. Whether verifying manufacturing or determining fitness for service, bolt and thread inspection is necessary for compliance with safety regulations. The condition assessment of riser bolts, structural anchor bolts, high tensile bolts, and the wide variety of other bolts and threads has advanced with non-destructive testing (NDT) methods, allowing earlier detection.

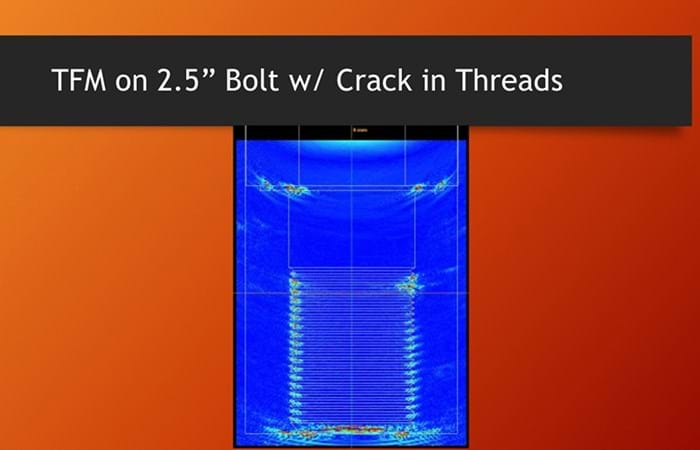

Suitable for Ultrasonic Testing (UT), bolts can effectively be inspected for corrosion and cracks. Phased Array Ultrasonic Testing (PAUT) for bolt and thread inspection can be performed for in-service structures, without needing to remove the fastener. This NDT method provides corrosion and crack detection with easy-to-interpret visuals of thread loss and other defects, with all information recorded for post-analysis and comparative monitoring.

The M2M Gekko® is a field proven flaw detector offering PAUT, UT, TOFD and TFM through a streamlined user interface, Capture™. Gekko combines high resolution and speed while reducing inspectors’ training time. A complete PAUT portable unit, it includes all basic and advanced UT features reinforced in a compact casing designed for field use. The innovative system provides superior signal quality and TFM resolution for improved detection, including around threads, offering high scan speed and productivity. Capture includes fully embedded scan plans with many geometries, for reliable interpretation of inspection data for a range of bolt types. The M2M Mantis™ is the light and economical version of Gekko, offering the same technologies and software with a 16:64 pulser-receiver architecture.

Eddy Current Testing (ECT) has proven to be a leading method for NDT of threads. ECT tools can be used to find partial and damaged threads, incorrect threads, and missing features or anomalies. Faster than thread gauges, ECT offers an expert solution for thread assessment. An evolution of ECT, Eddy Current Array (ECA) is a major improvement as it covers a larger area in a single pass, making the examination less operator-dependent and less time consuming, while providing clear 2D/3D images of the part being tested. The Eddyfi Ectane®, the most popular multi-technology test instrument on the market, enables highly effective thread inspection when paired with surface ECA probes. Eddyfi Technologies has the technical expertise to provide a custom solution for your unique thread inspection applications.

Alternating Current Field Measurement (ACFM®) is a well-established technique used to efficiently inspect subsea and topside structural welds while they are in service. It offers an attractive alternative to Magnetic Particle Inspection (MPI) because it enables quick scans on surfaces that are coated and unprepared. Moreover, it generates detailed electronic records regarding the location, length, and depth of the detected cracks. This information is crucial for making informed decisions about asset integrity and optimizing repairs. ACFM is equally advantageous when applied to both ferromagnetic and non-ferromagnetic drillstring threaded connections.

Fatigue damage is a common issue with threaded connections, necessitating regular inspections of downhole components. These inspections aim to identify any cracks present and determine whether repair or replacement of the component is necessary. Eddyfi's Universal Thread Probe (UTP) solution addresses this need by utilizing a single probe capable of inspecting any thread profile, be it pin or box. To ensure stable and consistent results, 3D printed shoes are employed to match the various profiles. This cost-effective approach has proven to be a rapid, clean, and reliable alternative to Magnetic Particle Testing (MT) and Penetrant Testing (PT) for this specific application.

Depending on your specific requirements, there may be one or many NDT techniques best suited for your bolt and thread inspection. Eddyfi Technologies offers a range of proven tools specifically for the advanced NDT of these critical components.