Eddyfi Technologies’ family of printed flexible probes (P-Flex) offers unparalleled customization capabilities for inspecting complex geometries, with superior coil performance and easy replaceability.

Features

- Thin and flexible design with a minimum bending radius of 2 mm (0.08 in)

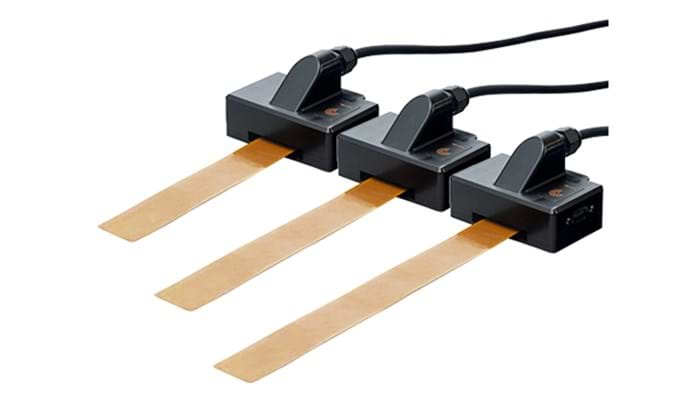

- Three probe sizes (small, medium, large) and expanded customization capabilities

- Detachable probe for easy replacement and reusability on various surfaces

- Superior coil uniformity and signal-to-noise ratio for high-quality inspection results.

Details

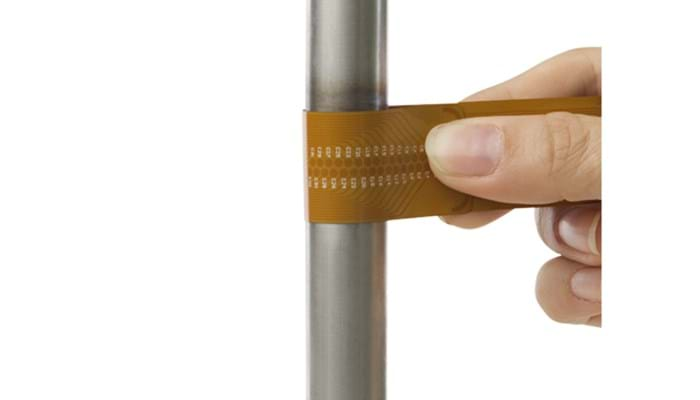

Flexible design for complex geometries

With a minimum bending radius of 2 mm (0.08 in), the P-Flex probes show exceptional flexibility for the inspection of complex and irregular surfaces. Their ultra-thin profile allows mounting easily onto a custom holder, facilitating access to tight or difficult-to-reach spaces. The same flexible probe can be reused with different holders and is detachable from its cable adapter to facilitate replacement. Gone are the days of time-consuming probe repairs when a single failing coil could delay an entire inspection.

Three coil sizes

To cover maximum inspection scenarios and offer the ideal compromise between coverage and detection performance, the P-Flex probes are available in three formats with different coil sizes: small, medium, and large. Selecting the right probe should be based on the smallest defect to detect, the required coverage of the array, and the nature of the material being inspected (ferromagnetic or not).

Highest signal-to-noise ratio

With printed coils density at the forefront of current probe technology, the P-Flex offers a higher signal-to-noise ratio (SNR) and coil uniformity compared to other printed probes on the market. Powered by Eddyfi Technologies’ SmartMUX and advanced multiplexing topologies, this probe family delivers an unrivaled probability of detection of small flaws.

ECA probe customization

The printed flexible ECA technology expands the capabilities for custom probe development. The engineering services offered by Eddyfi Technologies for the design and manufacturing of custom probes can now deliver inspection solutions for geometries that were previously not accessible. Custom probes with an extended array coverage can be built into holders of any shape and size. This allows confidently tackling the most demanding applications with equipment perfectly tailored to its task.

Specifications

GENERAL

- Small

- Medium

- Large

- 0.2 mm (0.008 in)

- 2 mm (0.08 in)

- Small: 34 mm (1.3 in)

- Medium: 56 mm (2.2 in)

- Large: 79 mm (3.1 in)

- Small: 0.5 mm (0.02 in)

- Medium: 1.0 mm (0.04 in)

- Large: 1.5 mm (0.06 in)

- Small: 1000 kHz – 4000 kHz

- Medium: 250 kHz – 1500 kHz

- Large: 250 kHz – 1500 kHz