Detecting Cracks and Corrosion in Aircraft Longerons

Aircraft are the backbone of several industries and, as such, are subjected to intense and near-continuous use, making preventive maintenance critical. Maintenance protocols are exhaustive but time-consuming, especially when fuselage and wing longerons are involved.

The Challenge

- Characterizing fatigue and stress cracks in the vicinity of longeron fasteners and mapping corrosion in a multilayered aluminum structure.

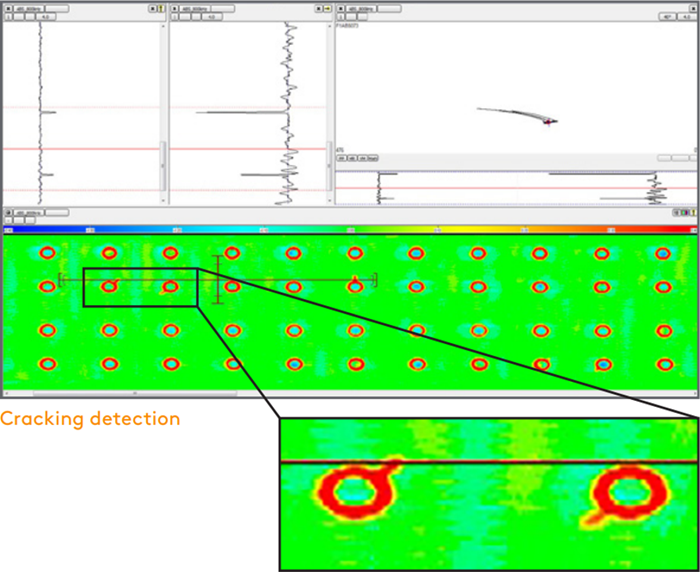

Longerons usually carry larger aircraft loads and help to transfer skin loads to the internal structure. Longerons nearly always attach to frames, ribs, or the skin of the aircraft. Fatigue and stress cracks eventually appear around the fasteners used to secure longerons to structures. Such cracks risk going undetected because they are small (typically 1.25 mm or 0.05 in.), they are near and under fastener heads, and often under surface coatings. The faying surface between longerons and skin is also prone to corrosion and must be inspected.

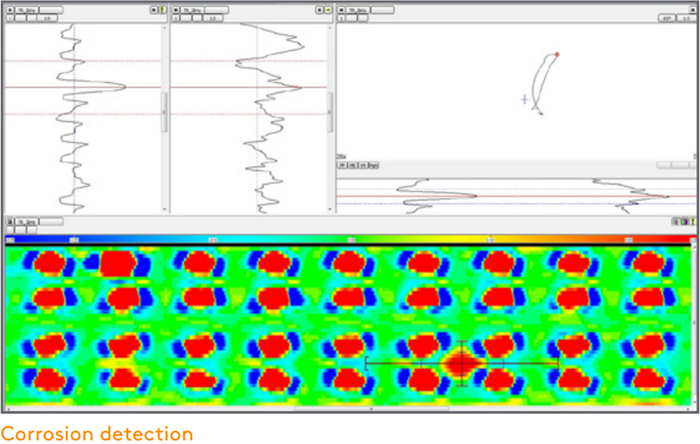

These situations present some interesting technical problems. First, potential cracks existing in the vicinity of fasteners are short, they spread in all directions, and they are often subsurface, making them difficult to detect. Second, hidden corrosion between the layers of multilayered aluminum structures is hard to locate. The required corrosion detection threshold is typically 10% in material loss in such structures.

To be truly practical, the solution must be able to detect these completely different types of defects with only one probe and one test instrument.

The Solution

- Using a single multiplexed, custom designed ECA probe to locate surface cracks and subsurface corrosion.

The instrument and the software to drive the solution—Ectane® and Magnifi®—already existed at the moment Eddyfi Technologies tackled this application. What was therefore necessary was a new type of probe capable of detecting surface and subsurface defects.

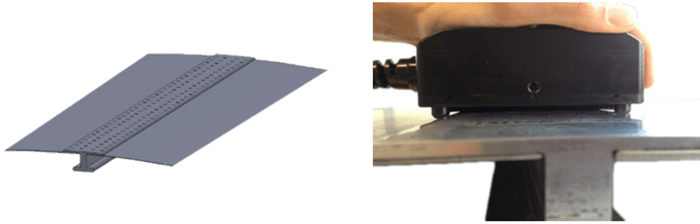

Eddyfi Technologies developed a hybrid Eddy Current Array (ECA) probe that would detect both types of defects within their respective tolerances. The probe therefore incorporates two arrays of coils using proprietary coil topology. The first is a high-resolution array using small, high-frequency coils to detect the surface cracks around fasteners. The second array is designed to detect subsurface corrosion.

The probe is also designed to be semiflexible, making it capable of conforming to skin curves. In addition, the rugged casing is much more adapted, compared to other available solutions, to the rough handling to which probes are often submitted.

Thanks to this powerful all-in-one design, the probe is able to detect corrosion build-ups ±5% of the layer thickness (e.g., down to 0.5 mm of a 10 mm layer), which is approximately twice as powerful as the initial requirement.

The probe is also able to detect 1.25 mm (0.05 in) longitudinal, transverse, and oblique stress cracks along the load path.

Benefits

- Quicker, more accurate inspections offering full archiving capabilities for data trending analysis. This translates into better planning and lower costs.

Historically, inspecting multilayered aluminum structures for cracks and subsurface corrosion required two sets of instruments, two different types of probes, and sometime even different software. The unified Eddyfi Technologies solution offers the following benefits:

Improved planning

By easily identifying cracks and corrosion between skin and longeron, it is e asier to plan long-term maintenance.

Faster execution

Switching from the crack inspection setup to the corrosion inspection setup is very quick. Because it does not require a new hardware setup and that the array probe offers wider coverage, inspections have gone from hours to mere minutes.

Better use of qualified personnel

Because they spend less time switching between inspection setups, qualified personnel can perform more inspections.

Data archives

Having access to archived inspection data allows performing advanced trending analysis to, for example, monitor crack/corrosion grow th and extrapolate their behavior.

This custom solution for longerons is the materialization of our ECA expertise. Taking a real-world problem and turning it into a solution that translates into lower costs and better performance.