Sizing Small Volumetric Defects in Fin-Fan Air Cooler Tubes

Fin-fan air coolers are widely used in the oil and gas sector. The main advantage of using such heat exchangers is that they cool fluids without the need for an external water source. By design, their fans generate a massive airflow, which helps aluminum-finned tubes dissipate heat. Such heat exchangers are powerful and they can be installed anywhere. The tubes in fin-fan air coolers are carbon steel.

The Challenge

- Sizing small volumetric defects in fin-fan air cooler tubes.

Detecting and sizing internal defects such as pitting, erosion, tapering, cracking at the tubesheet, or general wall thinning in a fin-fan air cooler’s aluminum-finned carbon steel tubes is difficult.

At present, there is no easy way to clean the tubes in fin-fan air coolers thoroughly enough to make IRIS easy. IRIS is, indeed, difficult, sometimes impossible in such tubes. That’s why the industry uses conventional inspection techniques for screening, and then confirms results with IRIS, if possible. All this makes for time-intensive inspections that are far from optimal.

Aluminum-finned carbon steel tubes are the most challenging tubular component to inspect for electromagnetic inspection techniques. The fins’ heavy influence on signal quality and their proximity preclude using RFT. Carbon steel is also strongly ferromagnetic and permeable, preventing eddy currents from penetrating tube walls and drastically affecting the signal’s phase spread.

Typically, conventional strip chart techniques such as Magnetic Flux Leakage (MFL), Partial Saturation Eddy Current (PSEC), and Near-Field Testing (NFT) are used to inspect aluminum-finned tubes, but none of them enable sizing defects. Only IRIS is capable of that, but as mentioned above, it requires that tubes be very clean. It also needs water and is very slow.

The Solution

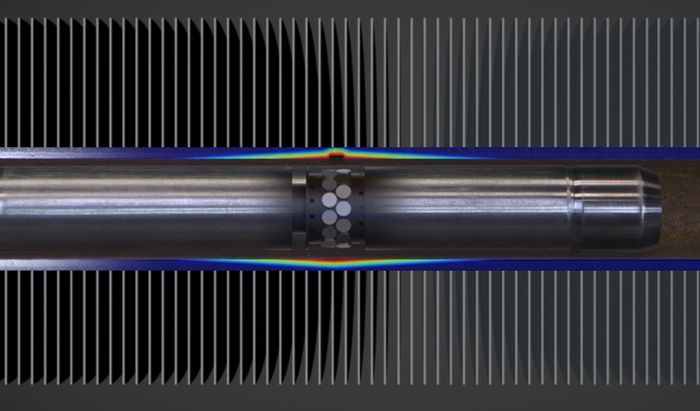

- A rugged, high-resolution NFA probe with enough receivers to reliably size indications.

To circumvent the limitations of current inspection methods, Eddyfi Technologies developed a multiplexed version of nearfield testing, called Near-Field Array (NFA).

NFA is a transmit-receive technique with a bobbin transmitter coil, an absolute bobbin coil, and an array of pancake receiver coils. The conventional strip chart absolute coil is used to detect and size internal erosion, tapering, and general wall thinning. The C-scan imaging generated by the array coils enables users to detect and size small, internal volumetric defects. NFA probes can also detect axial and circumferential cracking often found at the tubesheet.

The coils in NFA probes (up to 30) are multiplexed, which yields high-quality signals and enables C-scan imaging at a speed of 305 mm/s (12 in/s) in tubes ranging from 19.05 mm to 38.10 mm (0.75–1.5 in).

NFA also gives probes the necessary resolution to reliably detect and size small volumetric defects (approximately 3 mm or 1/8 in) in a single pass.

Unlike other inspection techniques, NFA probes are easy to use because they do not incorporate any magnets, which means they are easy to push and pull through tubes and are not as sensitive to pull speed as MFL probes.

Fin-fan air cooler inspections are often performed in cramped, hard-to-access locations, often without easy access to a power supply. Using the portable, battery-operated Ectane® with NFA probes significantly increases the productivity of inspections.

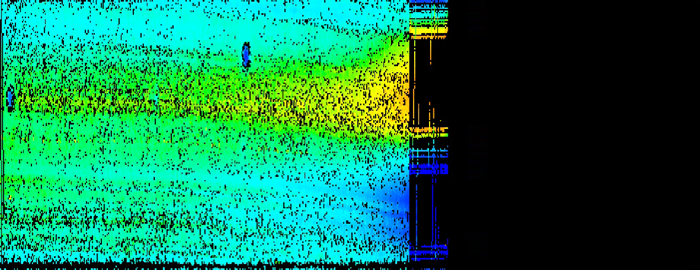

In the Magnifi® software, C-scan cursors are used to measure a defect’s circumference. Selecting the appropriate built-in amplitude-based sizing curves, the wall loss can be displayed as a percentage value in the impedance plane for reporting.

Furthermore, Magnifi can easily align absolute strip chart signals with C-scans with the slew alignment process. The automatic landmark feature yields axial defect location and axial coverage. The average pulling speed information given by Magnifi also enables operators to adjust the speed at which they pull the NFA probe, if necessary.

C-Scan Results of Volumetric Defects

IRIS Rescan

Visual Inspection Result

Benefits

- Faster, more reliable, durable, and easier to use than other conventional techniques, with C-scan imaging.

Using the NFA inspection solution has the following benefits:

Sizing

NFA technology gives probes the necessary resolution to reliably detect and size small volumetric defects in a single pass.

Easy to use

Because they do not have any magnets, NFA probes are easier to push and pull through tubes. They also do not require water or complex tools, making them much easier to use than IRIS.

Lesser sensitivity to pull speed

NFA probes are not as sensitive to pull speed as MFL probes.

Intuitive imaging

With Magnifi, NFA probe data can be displayed as intuitive 2D/3D C-scans that enable discriminating and sizing defects.

Durability

NFA probes are equipped with hardened-steel, wear-resistant guides to maintain a constant liftoff and yield more reliable results.