Fueling Economic Benefits with Remote Removal of Marine Biofouling

Ask an expertWith 90 percent of international trade transported aboard over 100,000 commercial vessels, merchant shipping is at the core of our global economy; this was acutely evident with the impact of the ship stuck in the Suez Canal in early 2021. Over the decades, ongoing innovations in vessel size, propulsion, construction materials, design specialization, and automation systems have helped to power the growth of maritime freight traffic. For marine operators in relentlessly competitive international waters, minimizing fuel consumption is a matter of economic survival. Newer reduced-sulfur fuels aimed at diminishing harmful emissions, especially when it comes to cargo-standard bunker fuel, are simply not as efficient as their predecessors. Therefore, no matter how clean the diesel or marine fuel oil may be, the real challenge that remains is how to use less of it.

The Challenge

Increase fuel efficiency by removing marine growth on ship surfaces using a safer and more economical solution than conventional methods.

Barnacles and other sea creatures stick to ship hulls, generating what is known as biofouling. In addition to causing premature hull failure from corrosion, biofouling is, hydrodynamically speaking, a drag. Hitchhiking plants and animals slow the marine vessel, impeding speed and performance. According to the United States Office of Naval Research, by increasing water resistance, biofouling can boost a ship’s fuel consumption by as much as 40 percent. Since fuel accounts for up to half of marine transport costs, that figure translates into roughly a billion dollars a year industrywide. Moreover, increased fuel use from biofouling not only raises costs, but it also contributes to adverse environmental effects through higher emissions of carbon dioxide and sulfur dioxide.

Whether the need is to examine a ship’s hull for suspected damage at sea, to scrape away fouling while waiting to load or unload, or to carry out scheduled maintenance, marine operators rely on airlifting expert divers out to meet vessels in remote ocean territory. The time-consuming process introduces additional fuel emissions from dispatching helicopters around the globe, and the mathematics stop making sense from an environmental perspective too.

Feeling immediate pressure to enhance energy efficiency by reducing overall consumption, marine operators seek a better solution for cleaning ship surfaces without increasing the associated risks and high costs of engaging divers.

The Solution

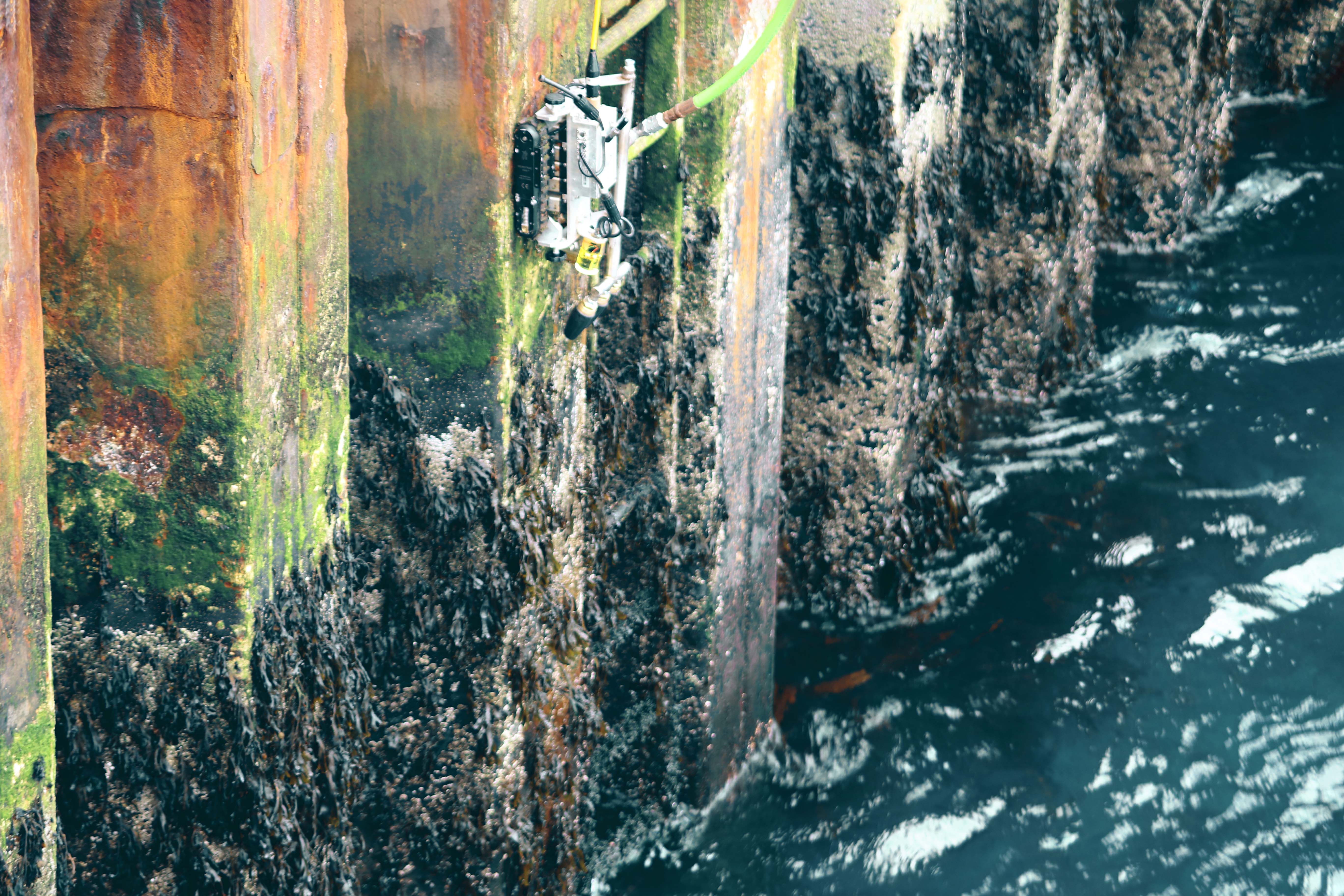

An adaptable robotic crawler fully steerable on vertical, horizontal, and inverted planes —already performing subsea inspections— readily integrates tooling for remote cleaning.

Technological advances are demonstrating how using an amphibious robot can save time, money, and most importantly, human risk factors in hostile marine environments. Employing robotic crawlers that have successfully performed remote operations under challenging circumstances outside the marine transportation sector addresses a wide range of issues without costly human interventions. Standard solutions can:

- assess the condition of vessels without the need for specialty personnel or dry dock,

- check for local damage to the hull,

- detect corrosion,

- and identify marine growth and invasive species.

These remotely piloted inspections deliver detailed information to the ship owner, in a format that can be retained from year to year, providing an ongoing service report. Furthermore, self-run assessments minimize the unforeseen by enabling scheduling of maintenance based on need rather than calendar dates.

Beyond inspection, Eddyfi Technologies leverages its versatile robotic platforms to offer custom solutions best suited for bespoke remote interventions. Based on standard magnetic crawlers trusted by industry leaders worldwide, commercial systems like the Magg™ have been outfitted with cleaning tools such as heavy-duty brushes or cavijet sprayers used to combat invasive marine growth found on a ship’s surface. The same crawler-mounted inspection cameras used to identify problematic areas can be used to confirm that remote cleaning standards have been met. Given the worldwide client success found with robotic solutions performing these mechanical tasks like inspection and cleaning, there is no need to place human operators in the potentially dangerous marine environment the unforgiving sea presents.

Learn more

Beyond Inspection

We create technology that enables people to perform tasks that they could not otherwise do, in places they could not otherwise go. OnSpec Robotics enable access to areas that are too dangerous or remote for direct human intervention, providing time and cost efficient operations. Learn more

Benefits

- Avoid propagating invasive species through biofouling (biofouling on shipping vessels is the predominant vector for the transport of nonindigenous species in marine environments)

- Reduce harmful marine fuel emissions

- Make the most of newer low-sulfur fuels

- Reduce helicopter transport fuel emissions

Beyond the immediate advantage of limiting fuel over-consumption from drag, there are direct corresponding environmental benefits.

At sea or in port, deploying robots makes both economic and environmental sense. Leveraging an adaptive design for infinite applications, Eddyfi Technologies custom robots have been successfully deployed for remote cleaning operations. Bring us your challenge for an innovative solution today.