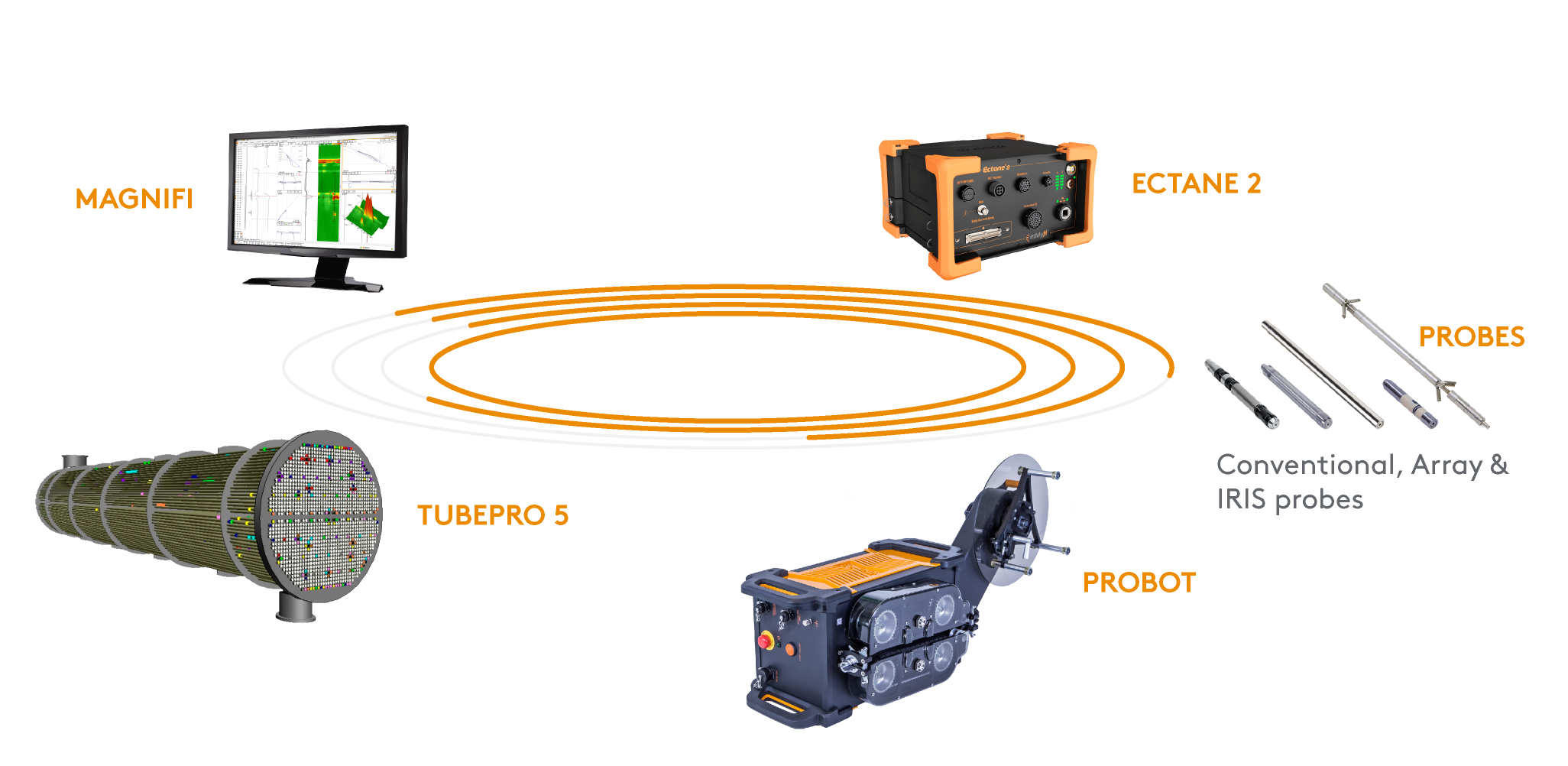

Eddyfi Technologies offers a complete NDT tube inspection solution. From data acquisition to report, our systems seamlessly work in sync to boost productivity, data quality, and confidence level in the report.

Details

The synergy created between our products makes the inspection teams increase their efficiency throughout the job:

- Probot allows to push the probe up to 100”/sec and record the data at the optimal speed for each technique (up to 70”/s).

- Easily create the tubesheet model from a picture or a drawing by using our detection tool in TubePro.

- Live 2-way communication between Magnifi and TubePro to send the tubelist and monitor the progress of the inspection.

- Flexible probes to inspect U-bend tubes in a single pass.

With the most up-to-date technology on the market, the Advanced Solution increases Probability Of Detection (POD) during your inspections:

- Crack detection and highest detection rate on the market with array probes.

- Encoded data and constant speeds make for more uniform data, making it easier for the analyst to review the data.

- Flexible probes for defect detection in the bends for both ECT and RFT.

- Assisted Analysis in Magnifi pre-analyses the data to help the analyst identify the tubes that need more attention.

At the end of the day, the inspection should be summarized in a report that you trust and value:

- TubePro is the reference in the industry, combining unique reporting features and the integration with Magnifi.

- Precise defect location with Probot for a thorough assessment of the equipment

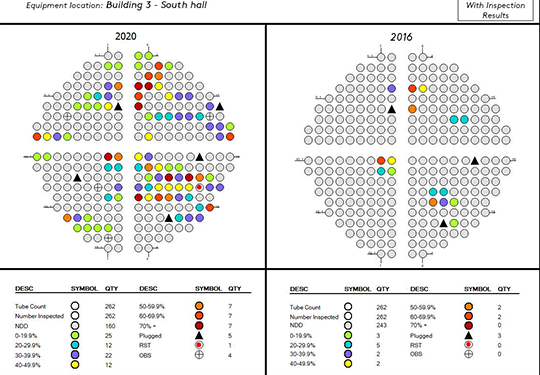

- Visual comparison of data sets from different years or from different techniques (eg: RFT and IRIS) for a given exchanger.

- Access to the 3D model of the exchanger in the PDF version of the report

The Solution Explained

Because every hour matter during an inspection, you can always count on the Probot to push and pull the probe at optimal speeds.

- Efficient

- Superior precision and data accuracy

- Better control on the human factor

Moreover, the Probot gives reliable and consistent data. From the very first to the very last tube, the signal is constant which makes the life of the analyst much easier when reviewing the data.

During tests conducted in Singapore compared the Probot to the manual inspection. Normally, the 600 tubes heat exchanger was inspected in 1.5 days at a rate of 400 tubes per 12 hours shift, which represents 33 tubes/hr.

What happens when the Probot gets to do the job? Productivity is increased 3-fold resulting in the whole job being done in 7 hrs. For that inspection, the Probot was working at a rate of 86 tubes/hr.

Finally, in addition to ECT and RFT, the Probot can also be used for IRIS inspections as we have developed a slipring to feed water to the probe.

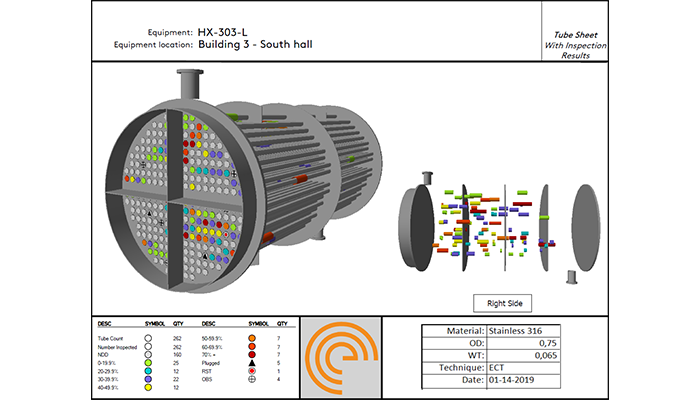

When it comes down to the report, TubePro offers the inspection companies the best tools on the market to generate an insightful report. As for the asset owners, when receiving a report that can include tables, graphs, drawings and more, you have access to visualization tools that help you make a better assessment of your equipment.

Moreover, TubePro helps the integration of our product line in one complete solution. By creating the link with Magnifi, the synergy is enabled, allowing the inspection to be more efficient at getting the job done and handing out the report.

Two of the key features are:

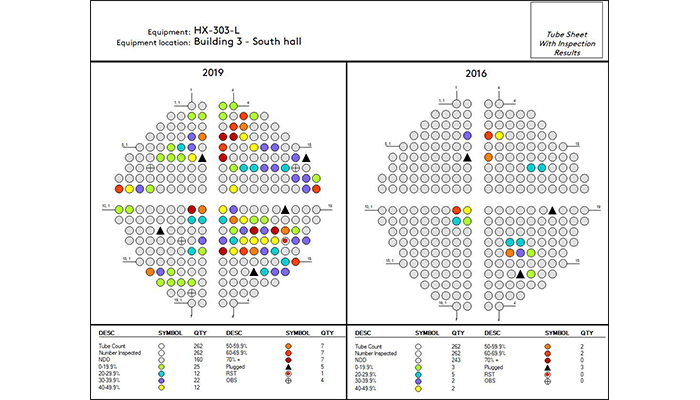

- 2 data sets comparison: this tool offers the capability of comparing results from a previous inspection, allowing to see the trends. It is also possible to compare the data from 2 different techniques on the same tubesheet drawing.

- 3D model in PDF report: A 3D model of the equipment can be inserted in the PDF report. This model can be zoomed in and out and rotated by the user. It enables the asset owner to see general trends that could emerge from the results.

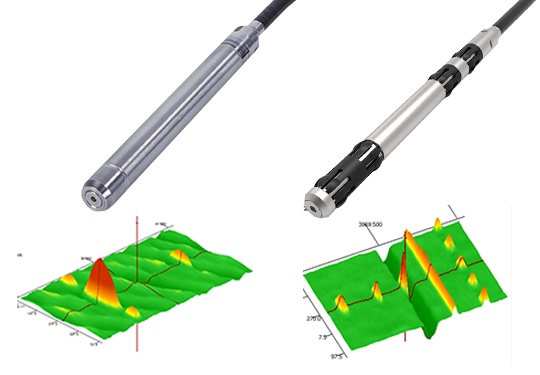

When it comes to non-ferrous tubes, there are no better tools to detect and size the defects.

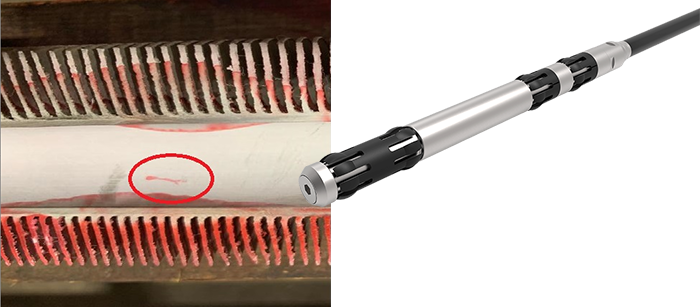

Unaffected by the external fins, the DefHi can detect and size both circumferential and axial cracks.

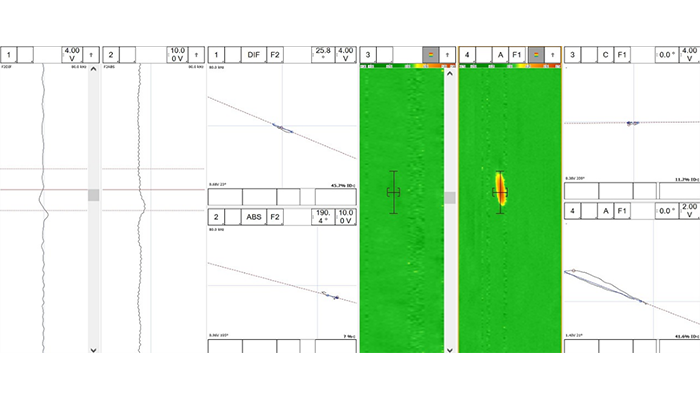

In a recent inspection in Qatar, 1” x 0.065” SS 316 tubes were initially scanned with an ECT Bobbin probe. From that initial inspection, 11 tubes were identified with axial cracks. Wanting to increase the level of confidence in the results, the tubes were rescanned with the DefHi probe.

The Results: 33 additional tubes were identified with indications.

The pictures shown to the right represent an example of the data collected with the associated tubes. The later ones were cut in half and LPT (liquid penetrant testing) was used to visualize the defects.

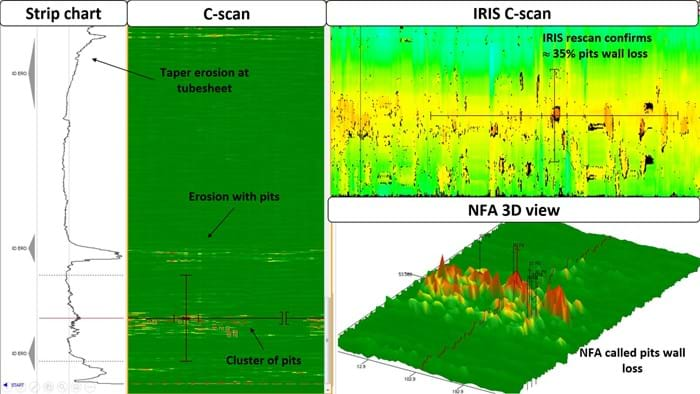

By design, aluminum-finned carbon steel tubes are some of the most challenging tubes to inspect. The external aluminum fins of these tubes greatly influence the quality of signals, making it difficult to detect and size any defect types.

Historically, IRIS has been the only solution for sizing defects in those tubes. However, this technique based on UT, requires water, the acquisition time is long and cracks remain elusive.

Our solution suggests to use the NFA as it's the best screening tool available. Used in combination with the Probot, it provides a first assessment of the tubes at blistering speeds. The array capabilities enable a very high Probability Of Detection (POD) and the IRIS can only be brought in for proof-up after the initial screening.

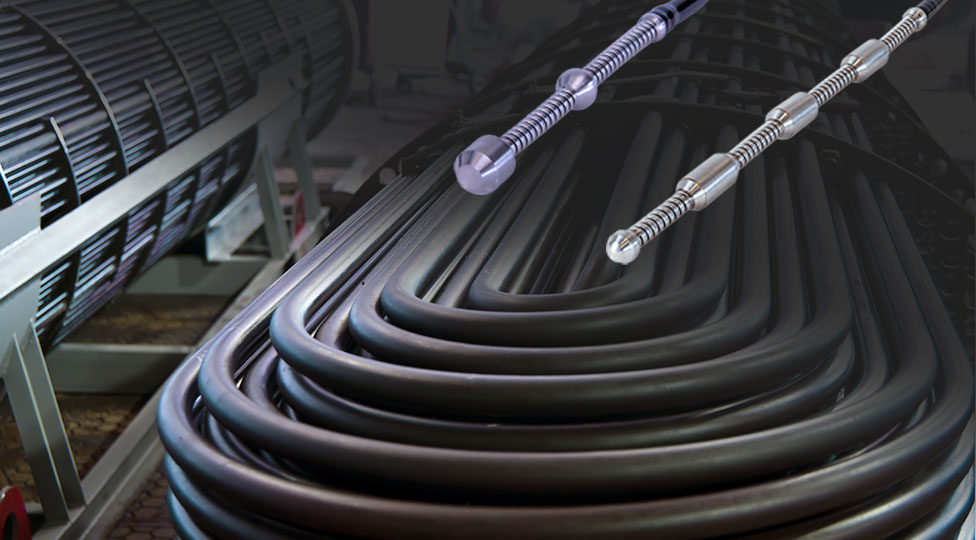

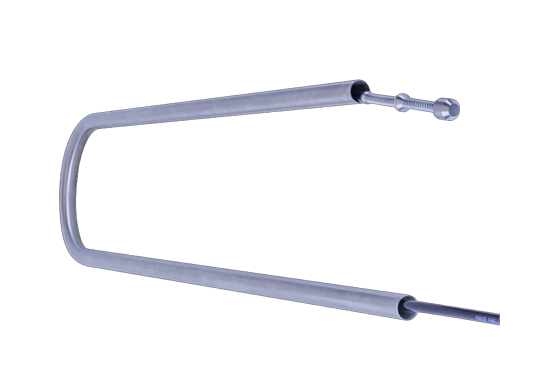

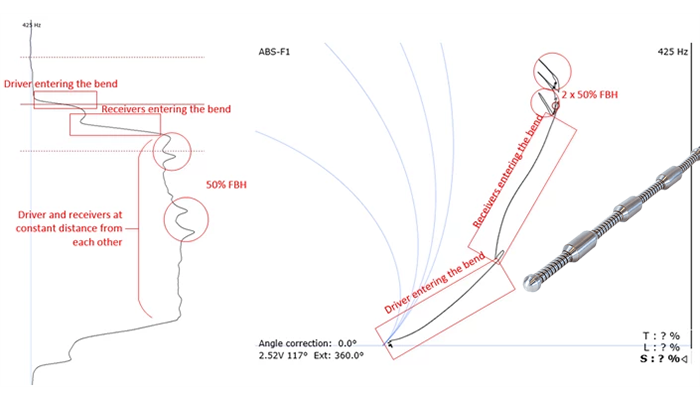

Our latest tests have confirmed that it is now possible to detect the defects in the bend section of U-bend tubes. Up to now, inspectors were left wondering what they can do to inspect the dends as they are hard to reach and very few techniques can offer enough precision to detect the defects. Our unique flexible design allow to pass 3" bend radius (180°) for ECT and 6,5 times tube OD radius bend (180°) for RFT. From the image to the right, we can clearly see that we can identify the defects in the bent section.

The RFT Single-Driver Flexible probe is a great time saver as both straight and bent sections can be inspected in a single pull.

In the world of automation we live in, our Assisted Analysis (AA) module is there to pre-screen the data so the analyst can focus on the indications that require most its expertise.

When joining forces with the AA module, Magnifi can validate that the data was properly acquired and that it’s ready to be analyzed. Moreover, by setting up detection windows, the data can be pre-screened, and potential defect location identified. Finally, tubes that contain no indication are marked as NDD and the analyst can spend less time reviewing them.

At the core of our product line, you can rely on these two work horses to get the job done.

On the field for almost a decade, the Ectane 2 and Magnifi are the world leaders in tubing inspection for the Oil & Gas market.

Exclusive Content

Webinar - Optimize the Asset Integrity management in Oil & Gas Refineries and Chemical Plants

This webinar features a demonstration of the Advanced Tubing solution, focusing on the seamless interaction between all the tools.

In this recording, you'll also learn about the:

- Challenges faced in integrity assesment of heat exchangers in oil, gas and petrochemical assets

- Ways to enhance the productivity, data quality and confidence level